Altair Multiscale Designer is a powerful tool for developing and simulating various multiscale material models. It is suitable for continuous fiber, woven, chopped fiber composites, honeycomb cores, reinforced concrete, soil, bone, and many other types of anisotropic materials.

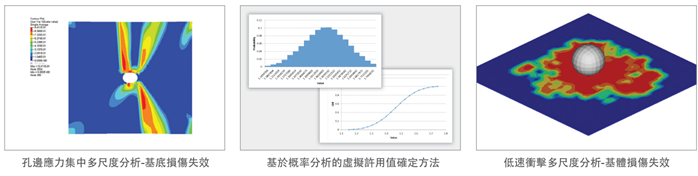

Applications include multiscale material modeling for design, ultimate failure, statistically based material allowables, fatigue, fracture, impact, crash, environmental degradation, and multiphysics simulation, and it provides plug-ins for commercial FEA solvers Altair OptiStruct、Altair Radioss、LS-DYNA and Abaqus.

【 Product Highlights 】

-

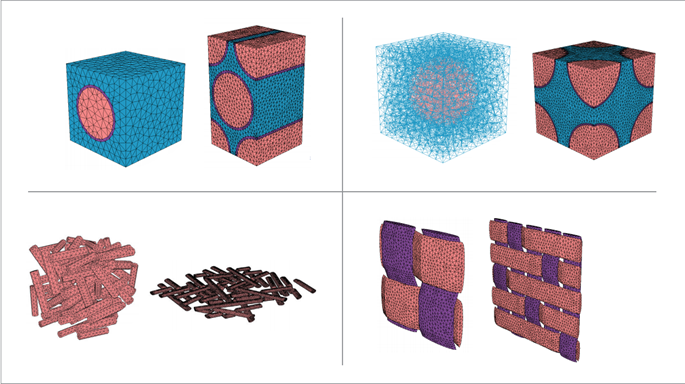

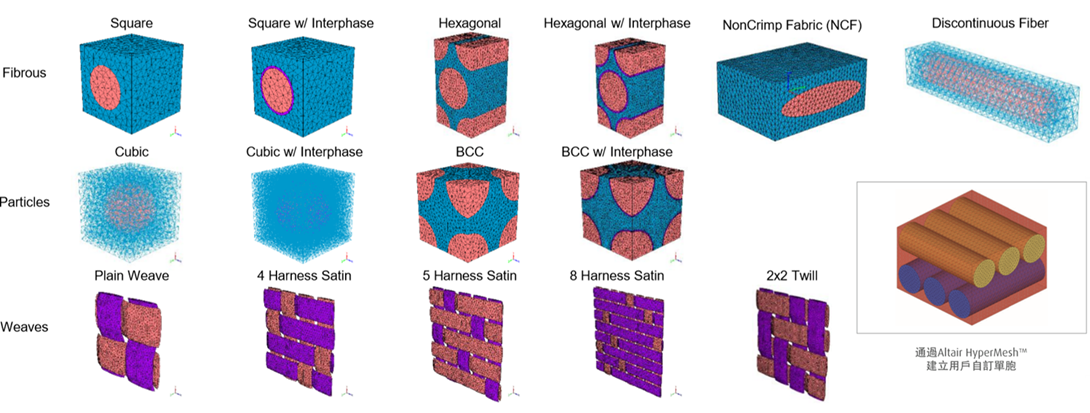

Applicable to continuous, long, and short fiber-reinforced composites

-

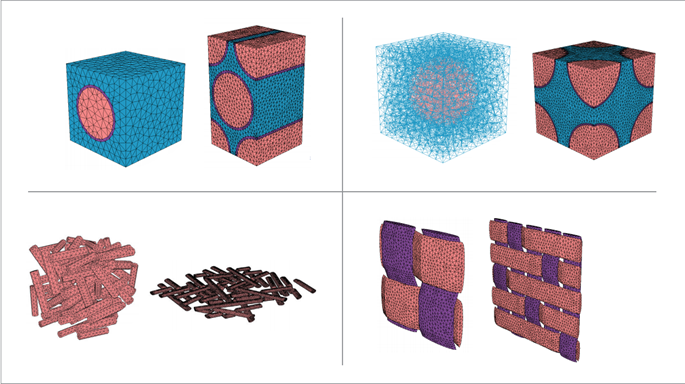

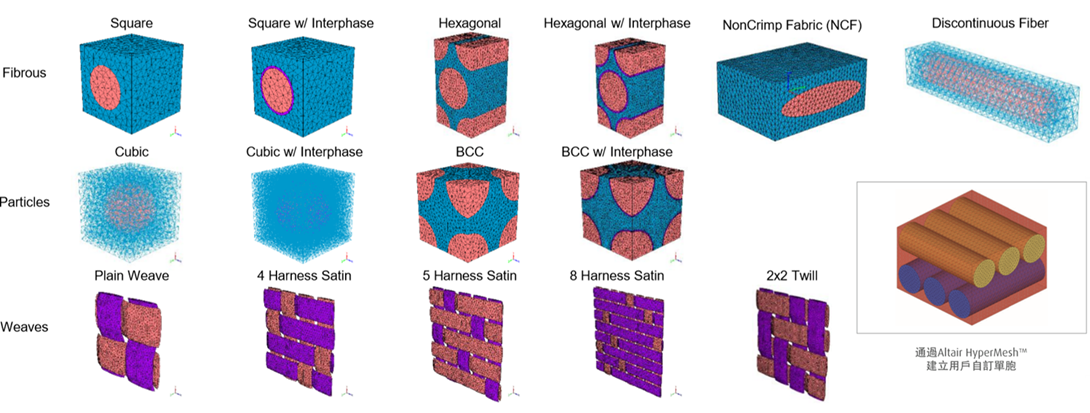

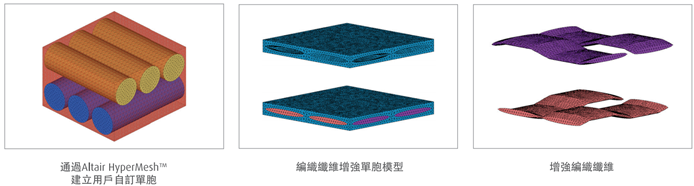

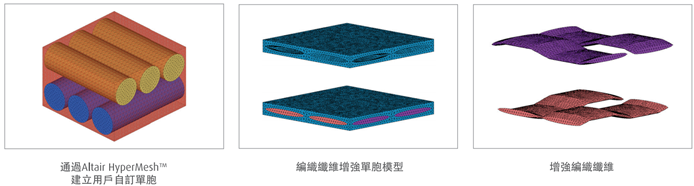

Built-in parametric unit cell models with support for user-defined unit cell models

-

Accurate and efficient simulation from nonlinear material behavior to ultimate failure

-

Ability to map fiber orientation from molding analysis to structural meshes

-

Built-in standard test models enabling virtual testing of materials

-

Provides efficient interfaces to commercial finite element solvers, supporting Altair OptiStruct、Altair Radioss、LS-DYNA and Abaqus

【 Advantages 】

Among the many multiscale modeling frameworks currently on the market, Altair Multiscale Designer uniquely combines ease of use, efficiency, accuracy, and multifunctionality.

Ease of use

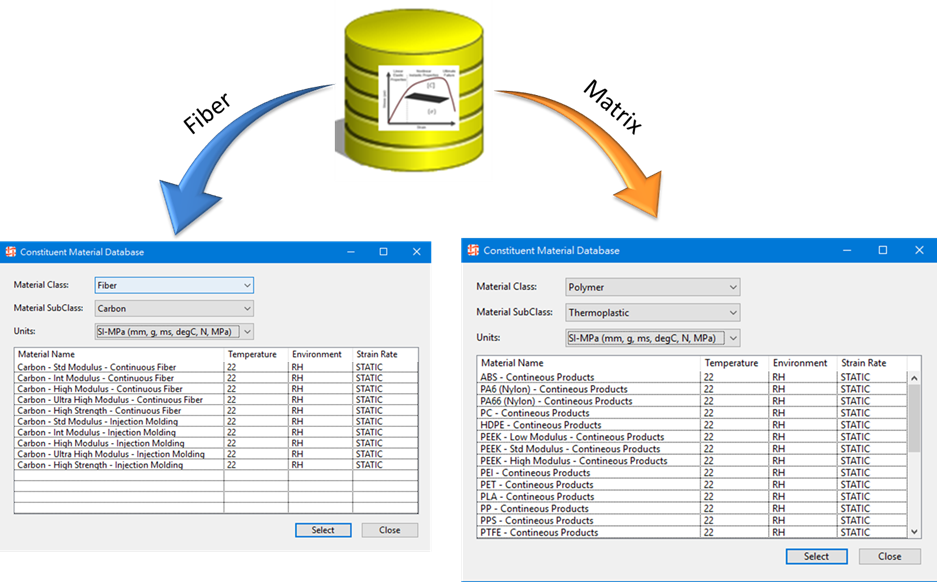

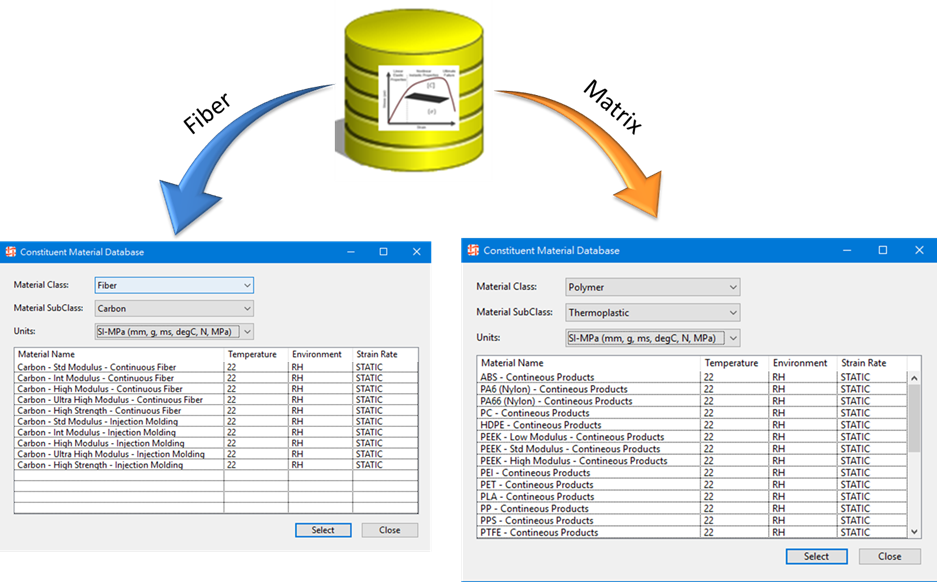

.......Multiscale Designer provides a convenient and efficient way to define and validate continuous and discrete composite materials. Users can define unidirectional composites and woven composites, and long or short fiber-reinforced thermoplastic and thermoset composites reinforced with fibers such as glass and Kevlar. The entire process can be completed quickly in four steps:

-

2D and 3D modeling environment outputting Cartesian, polar, and complex representations

-

Definition of linear material properties

-

Model order reduction

-

Definition of nonlinear material properties

The created multiscale models can be validated through virtual experiments. Once validated, the material models can be coupled with Altair OptiStruct、Altair Radioss、LS-DYNA and Abaqus and other well-known commercial finite element software to perform structural analysis.

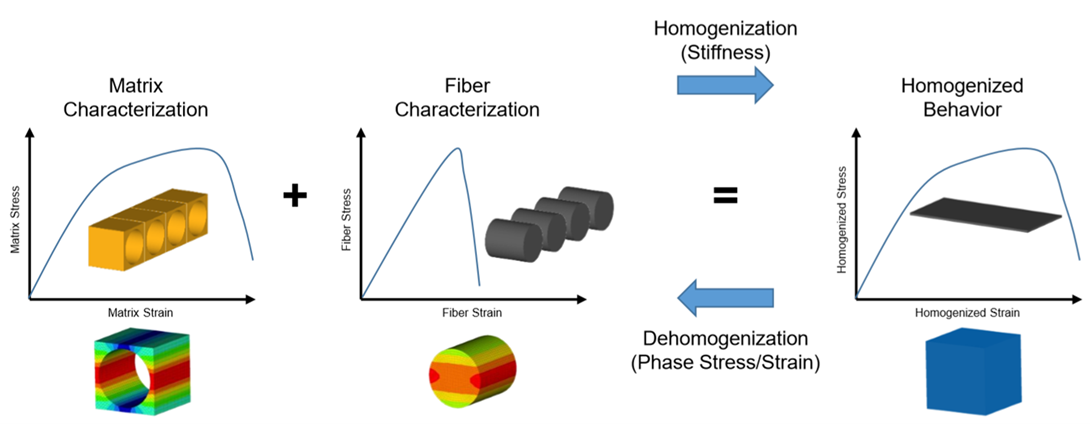

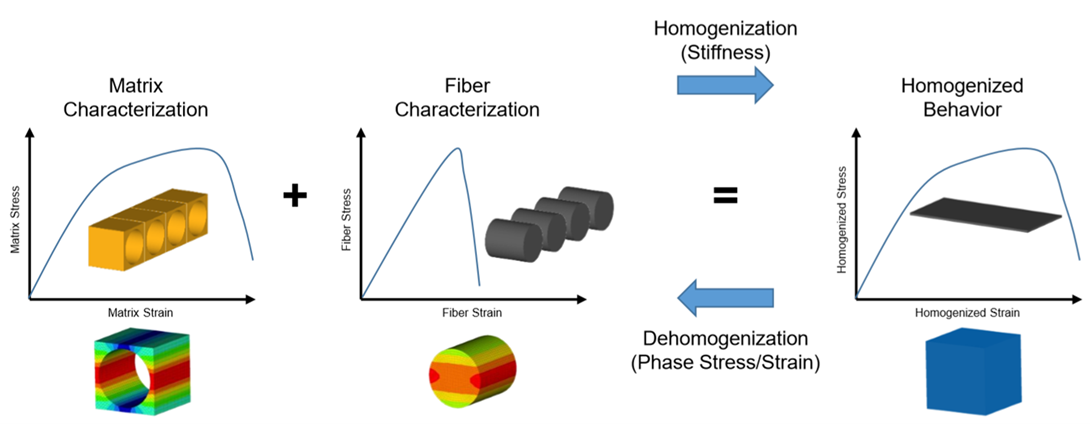

Computational efficiency

Traditional homogenization approaches for multiscale material analysis often cannot achieve both computational efficiency and accuracy at the same time. Multiscale Designer solves this challenge with a unique model reduction technology. It first builds a 3D unit cell model and then reduces this model. By solving the unit cell model once, the macroscopic anisotropic linear and nonlinear material parameters of the unit cell are obtained. During macroscopic finite element simulation, each integration point of each element calls these material parameters to compute stiffness and stress, without repeatedly solving the unit cell model, thus effectively addressing both efficiency and accuracy.

High accuracy

In the unit cell model, Multiscale Designer assigns dedicated nonlinear material models to the matrix and fibers. These include damage models for brittle materials such as glass fibers and carbon fibers, plasticity models for ductile matrices, and advanced combined damage models. These material models have been extensively validated for their accuracy on unidirectional composites, woven composites, and short-fiber-reinforced composites.

Versatility

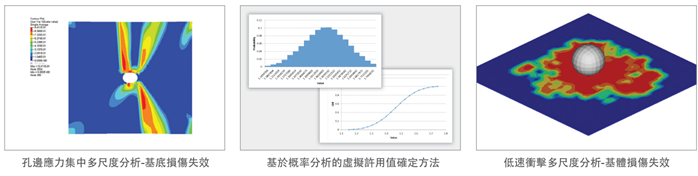

.......Multiscale Designer includes a built-in macroscopic finite element solver and a parametric library of standard specimens, including pure shear, pure bending, V-notched and unnotched specimens, enabling rapid multiscale simulations of these standard tests. Its stochastic analysis module integrates Monte Carlo and sparse grid stochastic analysis methods. Each material parameter can be defined by a probability density function using mean, variance, and probability distribution type. The outputs of the stochastic analysis are probability density functions, from which A- and B-basis allowables can be directly calculated.

【 Features 】

Mechanical property analysis and virtual material laboratory

Multiscale Designer - Mechanical is based on micromechanics and directly performs linear and nonlinear mechanical analysis on the micro-constituents. Its unique strain-eigenmode-based simplified unit cell model makes the computational cost of multiscale analysis comparable to that of a traditional single-scale macroscopic model.

Multiscale Designer - Mechanical provides both forward and inverse modeling capabilities. In forward modeling, users input textile architecture, constituent properties (fiber, matrix), and other process and mechanical parameters to predict macroscopic material behavior. In inverse modeling, users input macroscopic test data and partial constituent properties to back-calculate constituent properties and reconstruct macroscopic behavior. Inverse modeling includes linear elastic calibration and nonlinear calibration back-analysis.

Multiscale Designer - Mechanical has been validated against more than 50 benchmark problems on coupon and component levels for a wide range of composite product forms.

【 Stochastic analysis 】

Multiscale Designer - Stochastics provides both forward and inverse stochastic simulation capabilities. In forward stochastic simulation, the variability of the micro-geometry and constituent properties is assumed, and the probability distribution functions of macroscopic quantities of interest are computed. In inverse stochastic simulation, the probability distribution functions of micro-constituent properties are inferred based on the variability observed in macroscopic (coupon-level) experimental data.

Multiscale Designer - Stochastics can directly provide A- and B-basis allowables supported by experimental data.

Richin Tech is the “expert in CAE and AI data analytics”, and we have completed many successful case studies.

▶ Contact us now to obtain more information.

▶ Subscribe to the Richin YouTube channel to explore more CAE and data analytics.