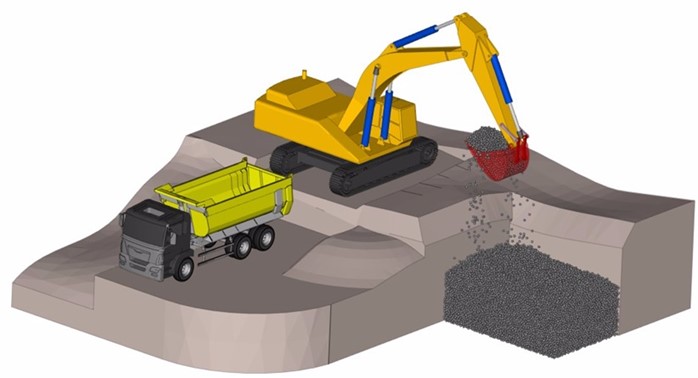

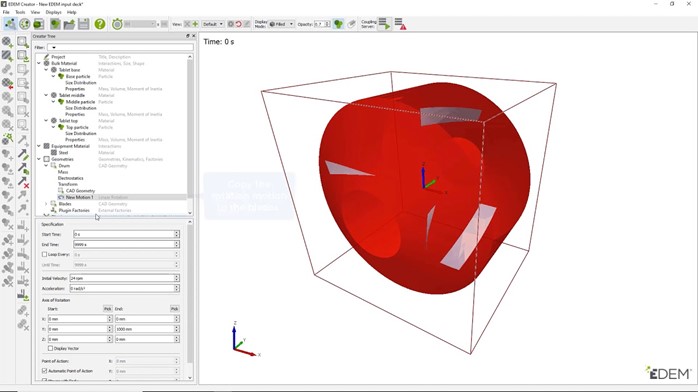

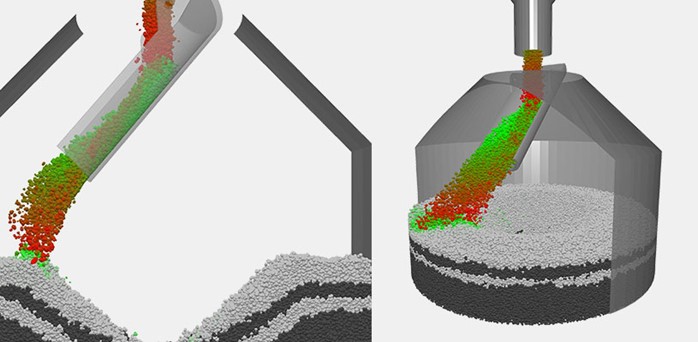

EDEM is a high-performance analysis software for simulating bulk and granular materials, and is the flagship product developed by DEM Solutions. Based on the Discrete Element Method (DEM), EDEM can quickly and accurately simulate and analyze the behavior of non-continuous materials such as coal, ore, soil, fibers, grains, tablets, powders… etc. EDEM can import 3D particle shapes and, by computing particle contact and collision forces and considering the effects of gravity, friction, and material cohesion, realistically calculates the motion behavior of material particles.

【 EDEM Coupled with FEA, CFD, and MBD Software 】

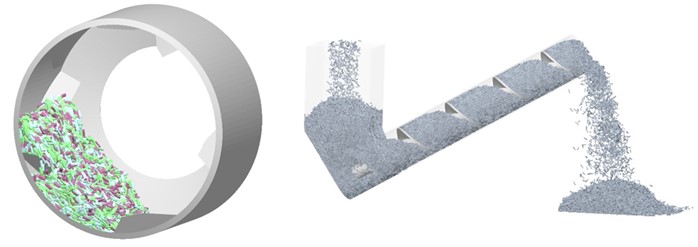

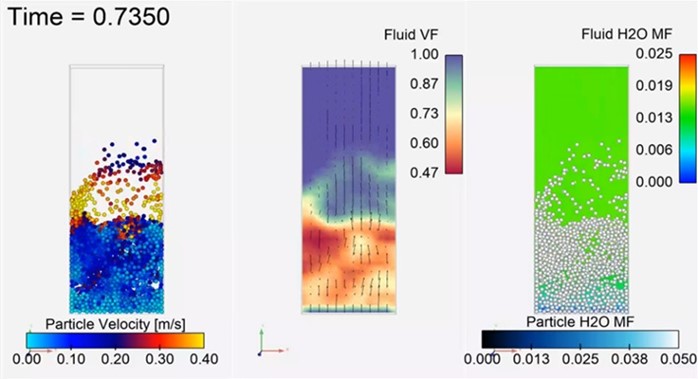

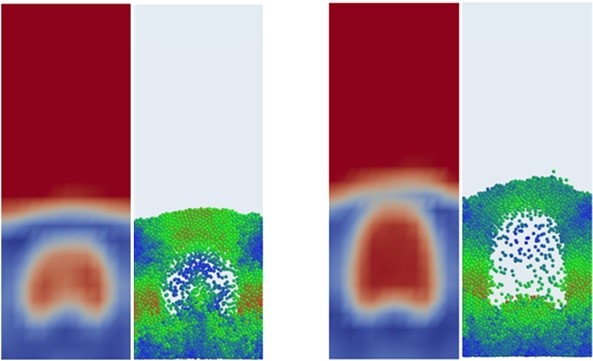

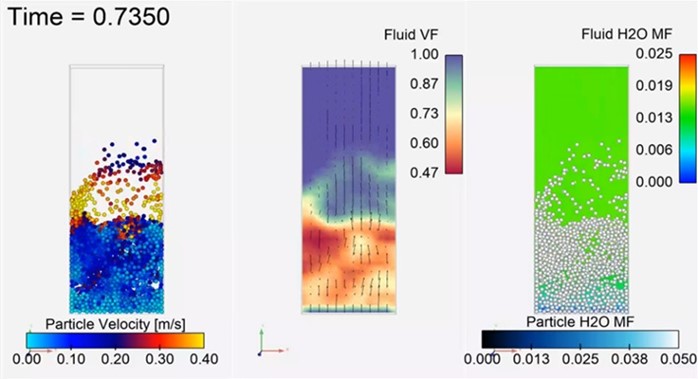

ANSYS FLUENT: simulate multiphase flow behavior between particles and fluid.

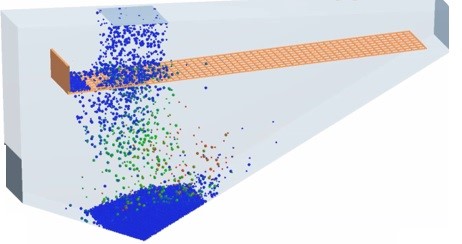

MSC ADAMS / LMS motion: simulate the impact of particles on multibody structural dynamics and their mutual motion.

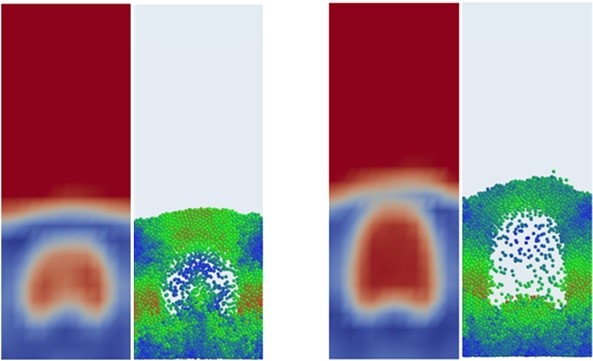

ANSYS FEA: simulate the coupled behavior between particles and structures to obtain the associated structural deformation.

|

|

EDEM is a powerful CAE tool. With its unique capabilities, we can study particle handling and production operations in a much more accurate way, gaining brand-new insights that were not possible before.

|

EDEM provides engineers with critical insights into how these materials interact with equipment under a wide range of operating and process conditions. It can be used as a stand-alone tool or in combination with other CAE tools.

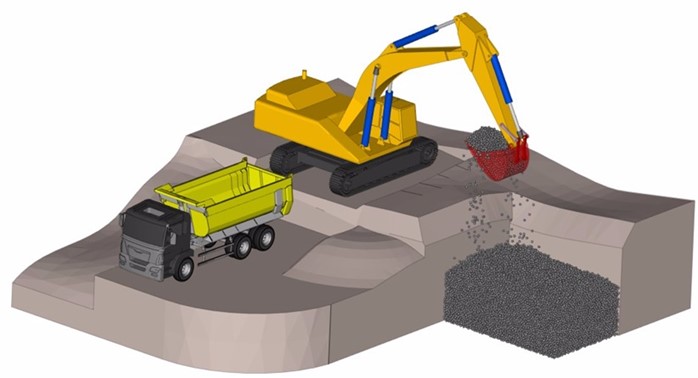

Leading companies in heavy machinery, off-road vehicles, mining equipment, steelmaking, and process manufacturing use EDEM to understand and predict particle material behavior, evaluate equipment performance, and optimize processes.

After Altair acquired DEM Solutions in 2019, EDEM capabilities were integrated into the multibody dynamics software MotionSolve and the computational fluid dynamics (CFD) software AcuSolve, providing brand-new coupled simulation solutions.

【 Product Highlights 】

Unique simulation of discontinuous media

Suitable for granular and discontinuous materials such as soil, powders, and more.

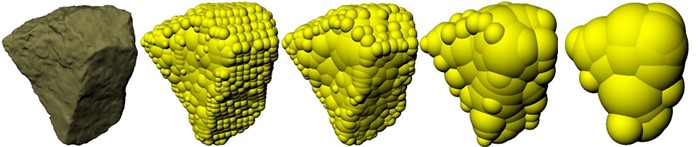

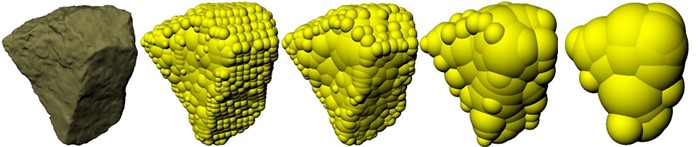

New multi-sphere fitting tool

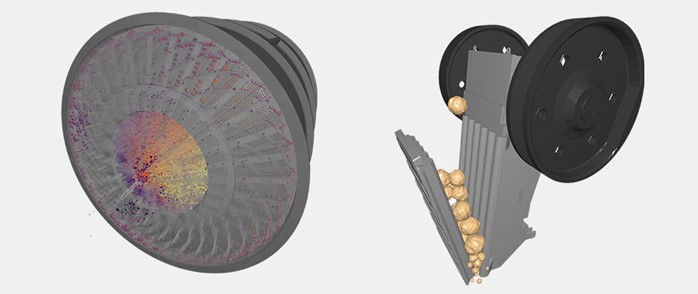

EDEM uses a computationally efficient and fully validated multi-sphere method to simulate materials of any size and shape. With this method, users construct shapes by overlapping multiple spheres, and can increase shape fidelity by increasing the number of spheres. With the brand-new sphere-fitting tool, users no longer need to manually arrange spheres to create the desired shape. The tool automatically generates multi-sphere particles that closely match particle shapes imported from CAD files. Users can control the number of spheres used and limit the minimum sphere size. With this tool, users can benefit from efficient multi-sphere simulations without manually building particle shapes.

Meta-particle creation

Many industrial applications involve flexible or stretchable materials, such as fibers, crops, and grass. With meta-particles introduced in EDEM Creator, users can easily create groups of particles, and then generate flexible fibers using an enhanced bonding model that supports meta-particles. Meta-particles are fully compatible with GPU. This greatly reduces the time and effort required to build flexible particle simulations, allowing users to create such materials in a straightforward way.

Built-in real-time material model library

Quickly and easily describe rocks, ores, soils, and powders using EDEM’s extensive library of pre-calibrated material models.

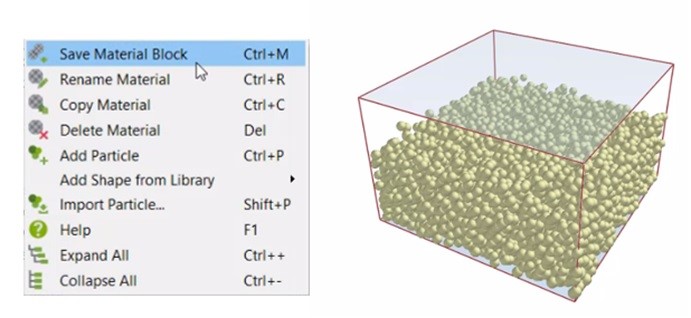

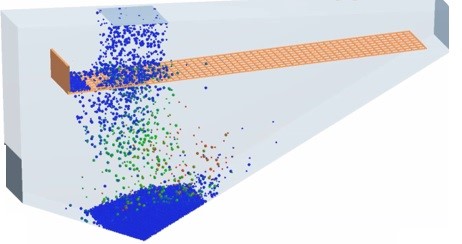

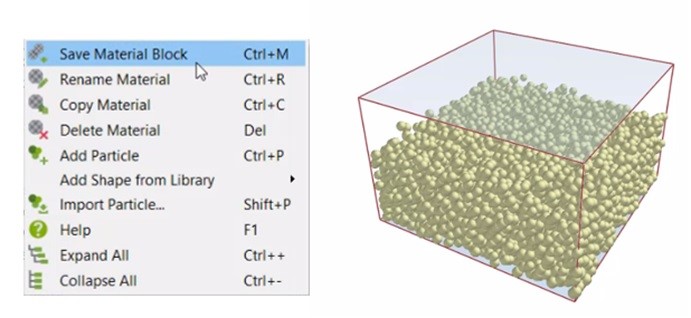

Material block dynamic factory

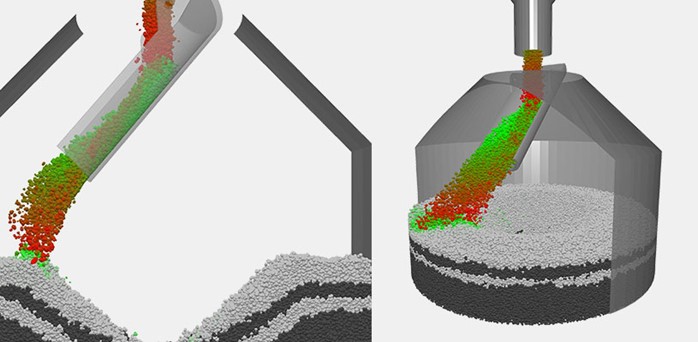

EDEM’s material block generation tool quickly and easily creates large material blocks by replicating and arranging smaller blocks.

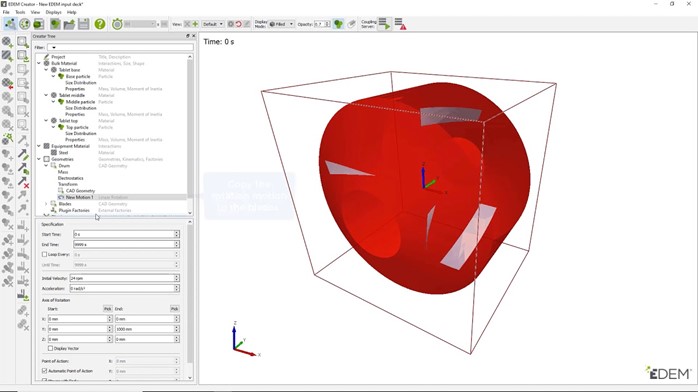

Motion control

The software now provides motion control functionality, enabling users to easily introduce geometry motion generated by applied forces or rotations.

Improved computational performance

EDEM already features a high-performance solver capable of running across CPU, GPU, and multi-GPU hardware to simulate large and complex particle systems with millions or even tens of millions of particles. EDEM 2020 further incorporates GPU computing to boost simulation speed and deliver even greater benefits. Benchmark tests show that, compared with CPU-only runs, using a GPU can dramatically increase speed. Compared with 12 CPUs, a single high-end GPU can deliver up to 15x speed-up. The GPU solver is compatible with API models, and the EDEM coupling interfaces allow all users to benefit from speed improvements regardless of simulation complexity.

Highly flexible post-processing

EDEMpy is a Python library for post-processing and analyzing EDEM simulation data, allowing users to easily extract specific data from the simulation platform and process it in a customizable and reusable way. The latest version includes a range of enhancements, such as new grouping functions for searching objects within box or cylindrical regions, new methods to extract sphere positions and radii, and performance improvements when retrieving contact data.

Integration with other CAE tools

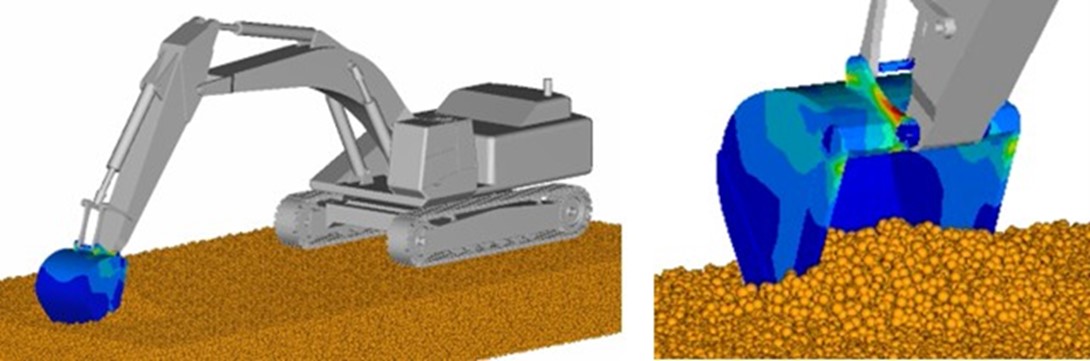

By integrating EDEM with other leading CAE tools from Altair or third parties, the application scope can be extended to multibody dynamics (MBD), finite element analysis (FEA), and computational fluid dynamics (CFD).

【 Advantages 】

Simulate any material

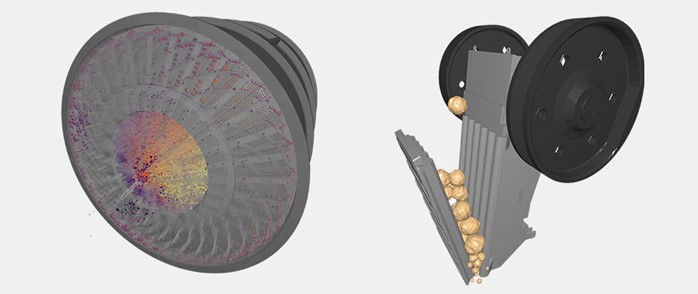

Use a validated and computationally efficient multi-sphere method or an industrial-grade polyhedral particle solver to model a wide variety of real materials such as large rocks, powders, grains, fibers, and tablets.

Realistic material behavior

Fully validated physics models can represent many types of material behavior, such as dry, cohesive, or compressible behavior.

Fast and easy analysis workflow

An intuitive and easy-to-use interface enables fast simulation setup. The built-in material model library provides ready-to-use material inputs. Combined with a powerful solver, simulation turnaround time is greatly reduced.

Advanced analysis

A comprehensive set of built-in tools is available for analysis and post-processing. Data export options and the Python library support further advanced post-processing.

Customization

Use the EDEM API to customize physical behavior for complex simulations and advanced material responses, such as wet coating, spraying, sintering, breakage, magnetic particles, and more.

CAE integration

Combine EDEM with FEA and MBD tools to apply realistic material loads in structural and multibody dynamics analyses. Coupling with CFD tools allows accurate simulation of particle motion in fluids for dust and debris analysis.

【 Features 】

-

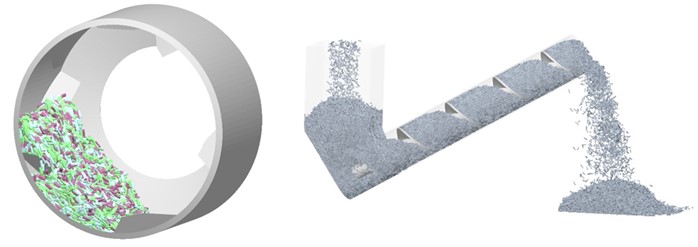

The same material block can be automatically imported into the simulation at specified time intervals. This is especially useful for inherently batch-type processes such as augers, belt conveyors, balers, and more. This powerful capability lets you use the output from one simulation as the input to another without re-running, saving a significant amount of time.

-

Motion control can be implemented via EDEM Creator, and this feature can also be combined with standard kinematics. It provides a powerful environment to easily define a variety of geometric motions that match real-world equipment motion.

-

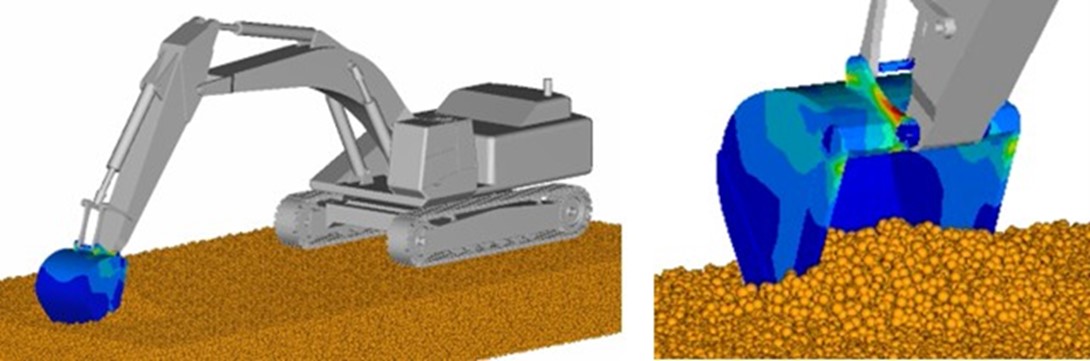

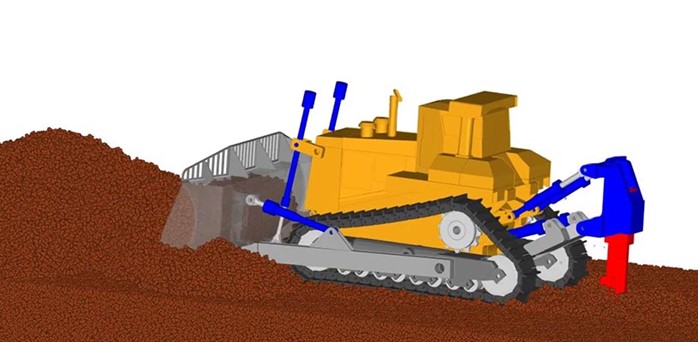

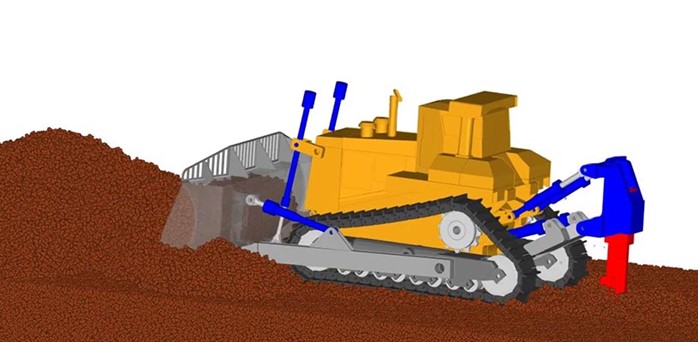

Coupling with MBD. Engineers designing heavy equipment can introduce realistic bulk materials into their MBD simulations and gain deeper insight into machine–material interaction. In addition to a broad range of existing solutions with other MBD software, EDEM can now also be coupled with Altair MotionSolve to perform flexible body analysis and observe stress.

-

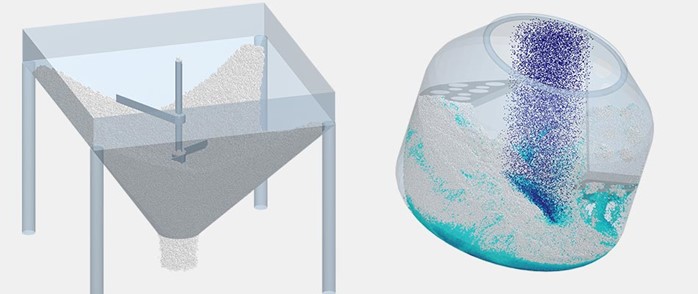

Coupling with Fluent. Users can accurately simulate a wide range of particle–fluid systems and transfer species data through this interface. This enables the simulation of complex thermal and chemical reactions (such as evaporation), and future updates will support combustion simulation. This opens the door to many new applications that rely on modeling such phenomena.

-

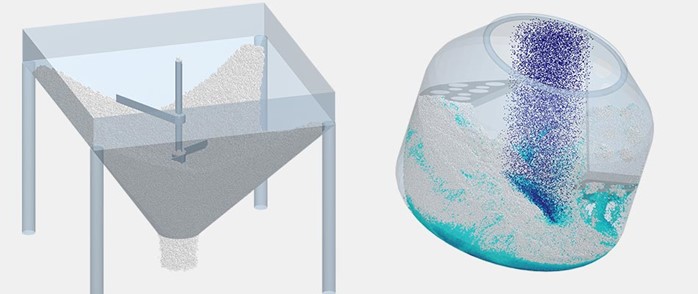

Coupling with AcuSolve. EDEM and AcuSolve support two-way coupling. This allows modeling of complex particle–fluid systems such as fluidized beds, pneumatic conveying, and solid–liquid mixing, where the fluid influences the particles and the particles also affect the fluid. Thermal transfer behavior can be considered to capture interactions among particles, fluid, and structures (particle–particle, fluid–particle, and solid–particle).

【 Application Areas 】

Construction machinery

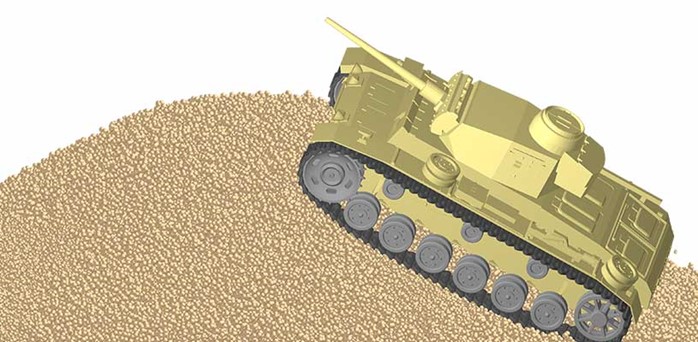

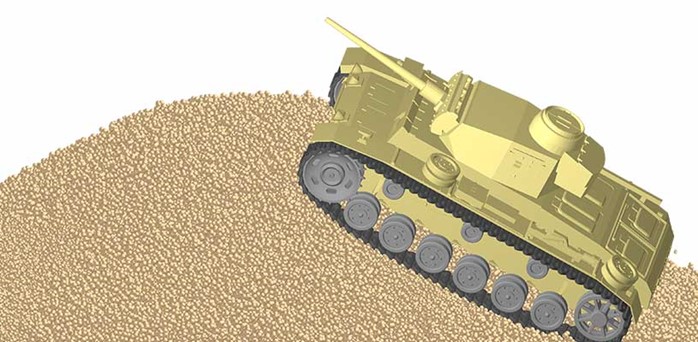

Off-road terrain

Mining equipment

Metallurgical equipment

Pharmaceutical, food, and chemical industries

Richin Tech is the "expert in CAE and AI data analytics", and we have completed many successful case studies.

▶ Contact us now to get more information.

▶ Subscribe to the Richin YouTube channel to explore more about CAE and data analytics.