Altair SimSolid is a structural analysis software for fast design processes that uses meshless analysis technology. Compared with traditional FEA, it offers the following advantages:

【 Advantages 】

Eliminates geometry simplification and meshing

SimSolid’s unique technology completely eliminates the tasks of geometry simplification and mesh generation, which are the two most time-consuming, highly specialized, and error-prone steps in traditional FEA analysis. With SimSolid, model preparation (similar to pre-meshing in conventional analysis workflows) can be completed within minutes.

Analyze complex parts and large assemblies

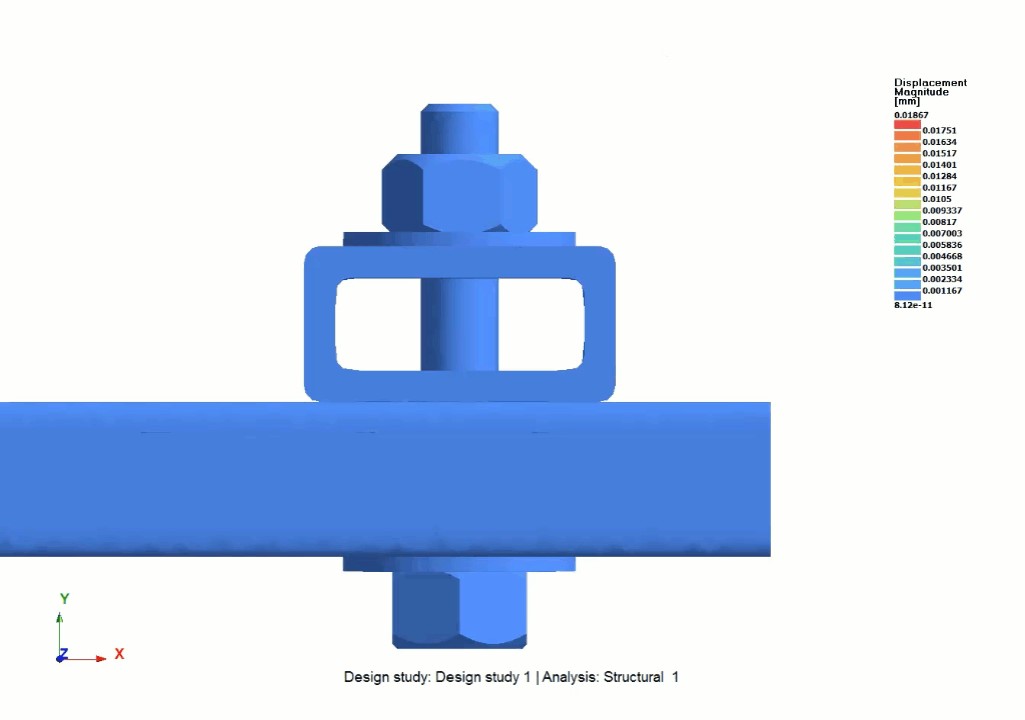

SimSolid is designed to analyze complex parts and large assemblies that are difficult for traditional finite element methods to handle. SimSolid can work with geometries that are not perfectly clean. Its assembly connection capabilities are industry-leading and can handle contact faces with gaps and overlaps.

Obtain analysis results in seconds to minutes

SimSolid is extremely fast. On an ordinary desktop PC, typical solution times are from a few seconds to a few minutes. With SimSolid, you can quickly analyze and compare multiple design variants. In addition, SimSolid allows accuracy control at the individual part level, enabling you to rapidly obtain highly accurate local stress or displacement results.

【 Product Highlights 】

-

Eliminates geometry model simplification and meshing. With SimSolid, model preparation can be completed in just a few minutes.

-

Analyzes complex parts and large assemblies. SimSolid can handle inexact geometries, and its assembly connection capabilities are industry-leading, making it easy to create and manage irregular contact regions.

-

Obtains analysis results in seconds to minutes. SimSolid is extremely fast, allowing rapid analysis and comparison of many different design alternatives.

SimSolid can analyze complex parts and large assemblies that are difficult for traditional finite element methods to handle, and it can do so efficiently on a standard PC. SimSolid is both fast and accurate, and its accuracy control method uses SimSolid’s proprietary multi-channel self-adaptive analysis strategy.

The computation engine is based on a breakthrough extension of the theory of external approximations, which is a generalization of the finite element method (FEM) and includes:

SimSolid does not use the nodal degrees of freedom (DOF) inherent in traditional FEA algorithms. SimSolid DOFs are functions associated with geometric entities such as model volumes, bodies, faces, lines (Lineclouds), and points (point clouds). This allows SimSolid to handle geometric imperfections and assembly issues such as gaps, penetrations, and irregular contact regions.

SimSolid controls solution accuracy through multiple passes of self-adaptive analysis. This adaptivity is always active and can be defined globally or in local regions. The method is extremely fast and efficient. It greatly improves computational efficiency without consuming excessive memory, making it possible to quickly analyze complex models or assemblies on typical desktop computers.

【 Features 】

Analysis types

Supports the following simulation types: linear statics, modal analysis, nonlinear statics (material and geometric), thermal analysis, thermo-structural coupled analysis, and linear dynamics (transient, frequency response analysis, and random vibration analysis).

Assembly connections and boundary conditions

-

Assembly connections: intelligent automatic connection, bonded, sliding, separable contact with friction, bolt connections, spot and laser welds, fillet/line welds, and virtual connectors.

-

Loads and constraints: immovable constraints, sliding constraints, hinge constraints, enforced displacement, forces, pressures, gravity, thermal loads, inertia relief, bolt/nut preload, dynamic loads, hydrostatic loads, bearing loads, and remote loads.

Material properties

Supported CAD formats

-

Direct data integration with cloud-based CAD systems

-

Standard STL files exported from any CAD system

-

Native geometry from major CAD systems: CATIA, NX, Creo, SOLIDWORKS, Inventor, and SolidEdge, etc.

-

Files in common neutral formats such as STEP, ACIS, and Parasolid.

Post-processing and reported result types:

-

Contour plots of displacement, stress, and strain

-

Deformation animations

-

Maximum/minimum value labels

-

Result display at any geometric surface location

-

XY plots

-

Reaction forces/contact forces

-

Bolt/nut forces

-

Spot weld forces

-

Modal frequencies and mode shapes

-

Modal participation factors

-

Factor of safety

Report generation:

-

Image thumbnails and titles associated with model graphic states, part visibility, and result displays

-

Synchronized model and result display

-

Export full-resolution result images

Common functions

-

Ability to handle mixed (SI and IPS) unit systems

-

Measurement tools (distance, ray probe based on local coordinates)

-

Global and local coordinate systems

-

Default views (front, back, left, right, top, bottom)

-

User-defined saved views

Richin Tech is the "expert in CAE and AI data analytics", and we have completed many successful case studies.

▶ Contact us now to get more information.

▶ Subscribe to the Richin YouTube channel to explore more about CAE and data analytics.