Introduction

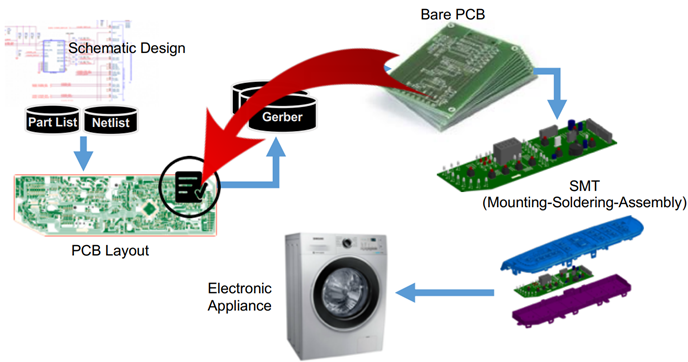

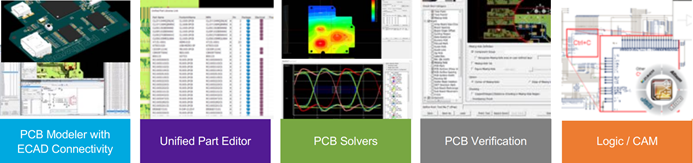

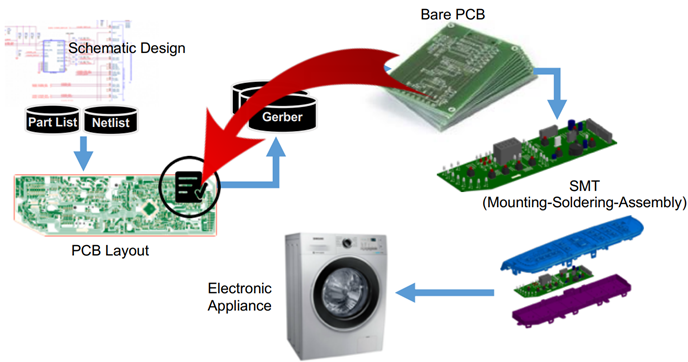

Altair PollEx is a highly integrated PCB design viewing, analysis, and verification tool suite for electrical, electronics, and manufacturing engineers. Altair PollEx is a PCB-level EDA software toolkit that covers design, analysis, manufacturing, and assembly. It can significantly shorten the development cycle while providing a common application platform for schematic engineers, PCB designers, CAE analysts, and manufacturing engineers. PollEx is an open solution that enables seamless data exchange among different ECAD and simulation environments.

Product Highlights

-

A strong global customer base and a leading position in Korea

-

Used by leading companies with top-tier electronics manufacturing technologies, including Samsung and LG

-

Fast and convenient visualization to verify and compare PCB designs from mainstream ECAD systems, while securely sharing designs

-

Identify manufacturing, assembly, and electrical issues early in the design phase to significantly reduce costs

-

Easily perform PCB SI and thermal analysis using an integrated parts and material library

Product Advantages

Innovative companies need efficient solutions to reduce PCB design–manufacturing iterations, while also taking into account the design and manufacturing supply chain. This is exactly where our comprehensive EDA software solution, PollEx, excels.

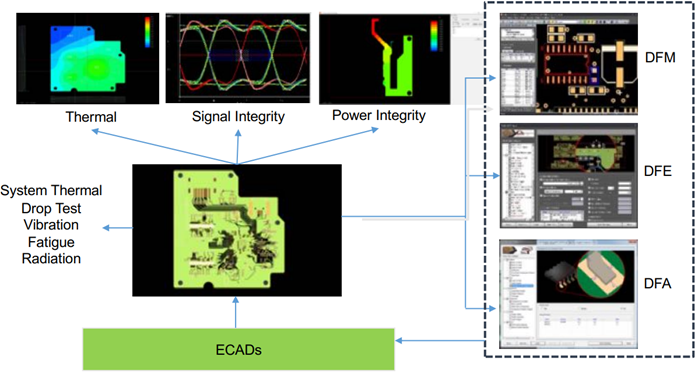

High Integration and Connectivity

Altair PollEx is the most comprehensive and highly integrated PCB design viewing, analysis, and verification tool suite. PollEx offers unmatched connectivity to all major ECAD systems, formats, and third-party PCB simulation tools. Through common applications and a powerful rule-based design checking system, it enables excellent Design-for-eXcellence (DfX), resolving downstream process constraints early in the design phase.

Rich Functionality

PollEx provides a wide range of capabilities, including querying, measuring, object searching, and various report-generation functions.

Detect Design Errors in Early Design Stages

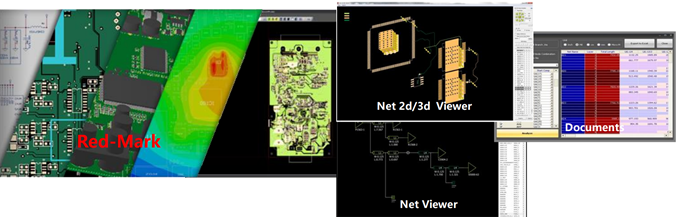

Problems discovered after design completion are difficult to solve and redesign costs are high. PollEx PCB Verification helps save substantial cost by identifying manufacturing, assembly, and electrical defects and failures at an early stage of the design. Designs are validated using rules derived from accumulated customer expertise, ensuring consistently high design quality.

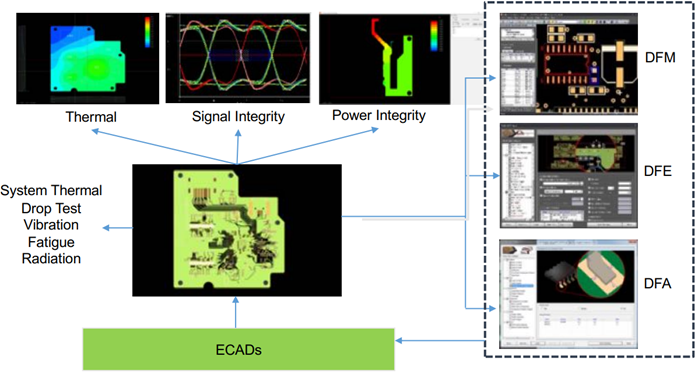

Simple, Fast, and Accurate Analysis

PollEx PCB solvers can address electrical and thermal issues in the early design stages. By conveniently accessing the component library information, configuring boards based on the built-in material library, and combining 2D and 3D parasitic models for analysis, the solvers deliver fast and accurate results.

In addition, PollEx DFE+ offers a unique solution by combining analysis and verification, enabling engineers to carry technical knowledge gained in current analyses into subsequent PCB designs.

Product Features

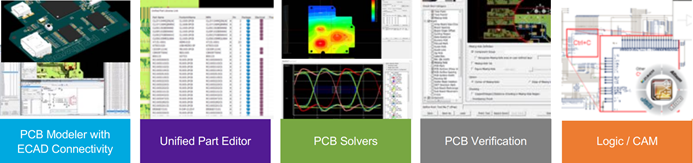

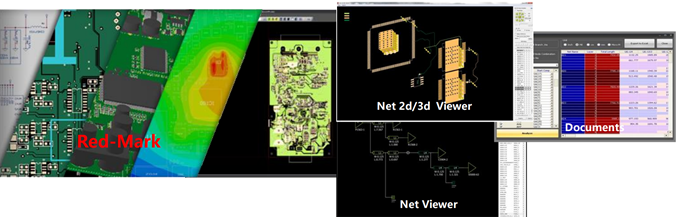

POLLEX PCB MODELER

Acts as the pre- and post-processor module and includes graphical visualization, data search, model browsing, dimension measurement, red-mark annotations, model comparison, sharing of an intelligent PCB database, support for parts, pad stack/via, 2D/3D net views, net analysis, BOM extraction, and report document creation.

It can read PCB data from all ECAD tools and, through simple automated detection, find and compare differences between PCB layout/routing, schematics, and BOM (Bill of Materials). It helps review and compare different PCB designs/revisions, including changes to properties, component locations and presence, routing connectivity, and physical layer stack-up.

POLLEX PCB CAM

-

Fast and accurate Gerber file viewing, supporting 274D/274X formats

-

Automatically filters when reading Gerber files, regardless of file type

-

Convenient layer/color control

-

Convert 274D to 274X format

-

Compare two different layer revisions using PollEx CP

POLLEX PCB LOGIC

Schematic design viewer (including cross-sheet search for references/components and nets)

Built-in logic symbol viewer with all attributes connectable:

-

PollEx CP: check differences between two schematic revisions

-

PollEx PCB Verification: rule-based DFE checks for design errors, red-mark annotation capability to store information inside the design, EDIF I/O format

POLLEX PCB SOLVERS

-

Finite-element-based electromagnetic field solvers: 2D methods for transmission line structures and 3D methods for vias. Built-in SPICE and IBIS solvers and various analysis types.

-

Signal integrity analysis (transient waveform analysis, eye diagrams, crosstalk-aware topology network analysis, with accurate consideration of impedance, delay, loss, and other characteristics)

-

Power integrity analysis (IR drop and power delivery network analysis for PDN, covering DC voltage drop analysis, decoupling analysis, and noise analysis)

-

PCB-level thermal analysis that considers conduction, convection, and radiation, dedicated to fast and accurate thermal analysis in early design stages

-

Finite element analysis (FEM) based on automatic meshing and a built-in material library

-

Can account for heatsinks, thermal vias, and wedge-locks

-

Can handle operating power and local boundary conditions for each component on the PCB

POLLEX PCB VERIFICATION

Rule-based PCB manufacturing inspection tools (PollEx DFM) and 3D package PCB assembly rule checker (PollEx DFA):

-

Rules are defined and input by users, leveraging customer manufacturing knowledge and engineering experience

-

This knowledge and experience can cover the entire SMT process (DFM includes 700+ check items and DFA provides 60+ check items)

-

Simple documentation (standard MS Excel format) preserves the history of engineering changes and links back to ECAD tools to correct design faults and errors.

POLLEX PCB VERIFICATION

Tool based on electrical performance design rules (PollEx DFE):

-

Create rules using PollEx templates based on customer knowledge of SI, PI, interference, and ESD to build a rule- and analysis-based tool (PollEx DFE+)

-

Built-in solvers for SI, PI, and thermal analysis

-

Users define target violation values as inputs, and after checking, may be prompted to modify the design

-

Includes 200+ DFE check items and 50+ DFE+ rule items

POLLEX DFM / DFA

-

Simple, intuitive, and customizable documentation exported to Microsoft Excel, including images of the PCB areas where errors/failures are detected

-

Maintain a history of engineering changes (up to 10 revisions)

-

Score PCB quality based on defined criteria

-

Support batch job checking

-

Connect to enterprise Product Data Management (PDM) / Product Lifecycle Management (PLM) systems via API functions

Contact Us

Richin Tech is the "expert in CAE and AI data analytics", and we have completed many successful case studies.

▶ Contact us now to get more information.

▶ Subscribe to the Richin YouTube channel to explore more about CAE and data analytics.