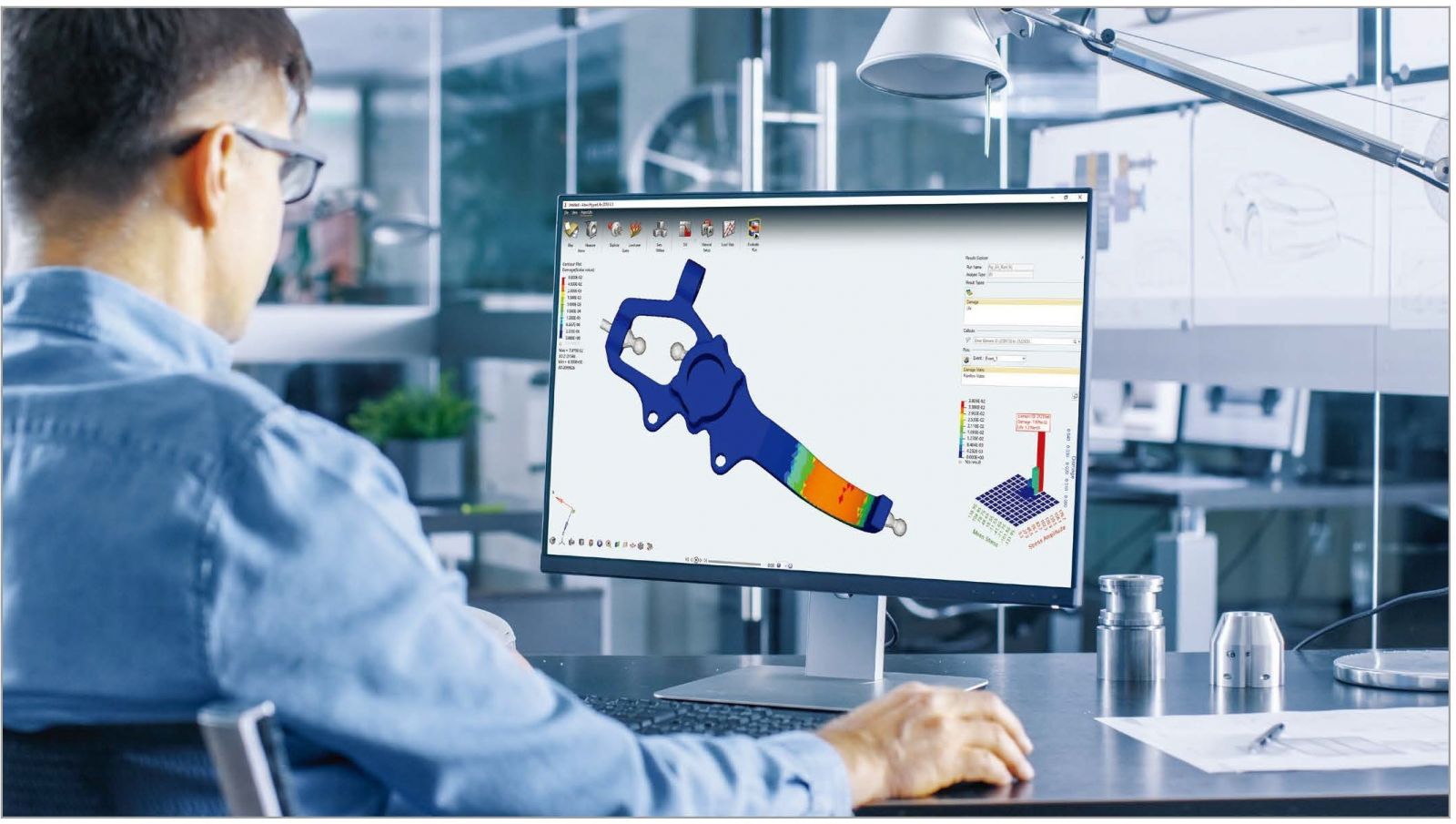

.......Altair HyperLife is a widely used fatigue analysis software that supports multiple FEA result formats and provides a built-in material database, enabling fatigue analysis based on static and dynamic analysis results.

|

Methods

|

Materials

|

Load history

|

【 Product Highlights 】

- Fast and reliable fatigue calculation software

- Integrated fatigue analysis workflow based on CAE analysis results

- Provides more than 500 material data sets and fatigue parameter estimation tools

- Fatigue evaluation functions based on industry standards (FKM, EC3, DVS1612)

【 Advantages 】

Ease of use

An easy-to-learn and easy-to-use interface ensures that both beginners and experienced engineers can quickly perform fatigue evaluations.

Solver neutral

Results from widely used FEA solvers can be used directly as input files for HyperLife.

Accelerated result evaluation

Multiple parameter changes and analyses can be performed within a single task, saving time and accelerating fatigue result assessment.

【 Features 】

Fatigue analysis methods

Provides uniaxial and multiaxial fatigue evaluation criteria along with various mean stress correction methods. For uniaxial fatigue, multiple evaluation stresses are available; for multiaxial fatigue, a critical plane approach is used.

For strain-based fatigue, Neuber elastic–plastic correction is used for uniaxial fatigue, while the Jiang-Sehitoglu correction is used for multiaxial fatigue.

The safety factor is calculated using the Dang Van multiaxial fatigue criterion to predict whether a component can achieve infinite life.

Weld fatigue supports both spot weld and seam weld evaluation.

Spot weld fatigue is evaluated using the Rupp structural stress method, and supports using CBEAM, CBAR, CWELD, and CHEXA elements to model spot welds.

Uses the VOLVO structural stress method, with seam welds modeled using shell elements. Multiple weld types are supported, and weld toes and weld roots are automatically identified and evaluated for fatigue.

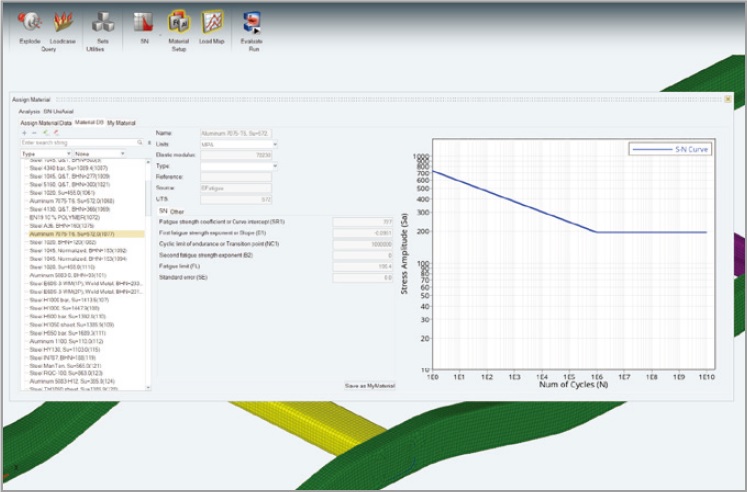

HyperLife provides a material database that allows users to assign materials directly to corresponding components, and modify material data as needed. Fatigue life can be estimated from UTS. Users can also create their own materials.

Signal processing

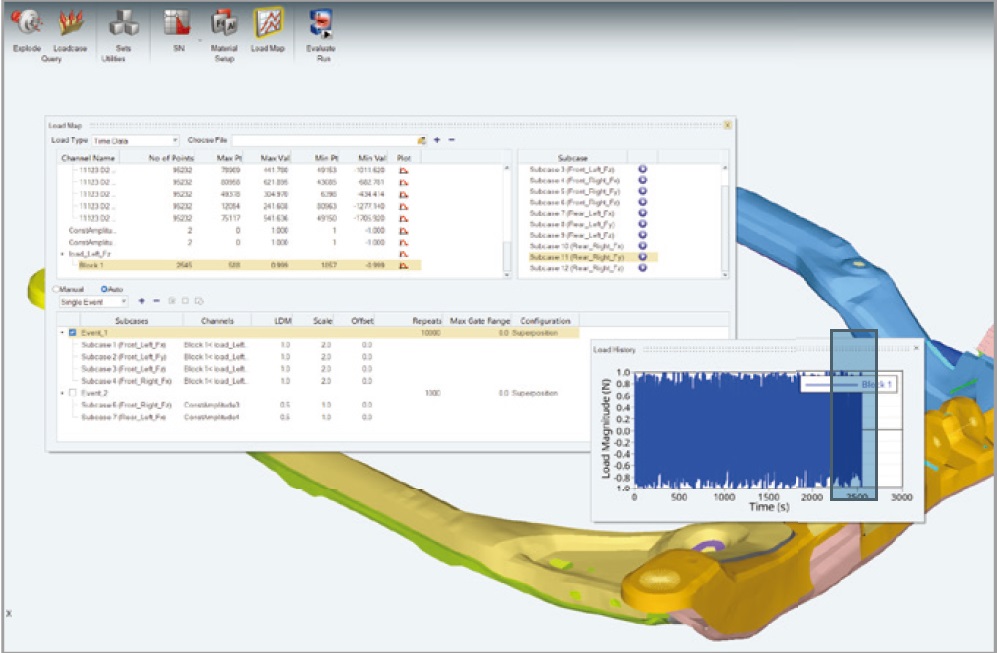

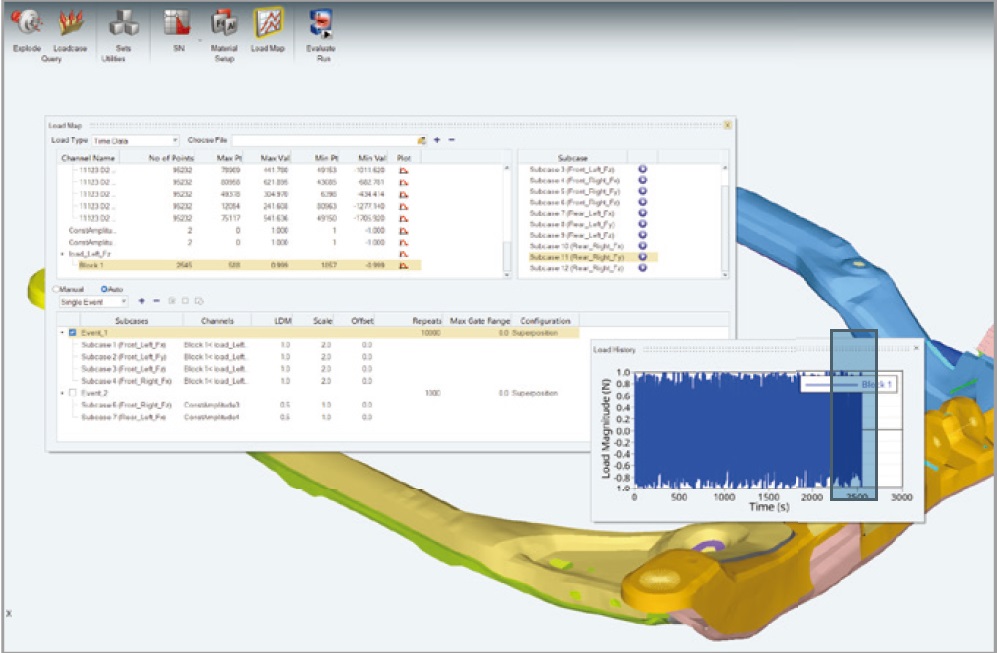

The LoadMap tool provides simple and reliable signal processing capabilities. Fatigue events can automatically or manually link load cases with load histories, and commonly used load history files such as DAC, RPC, and CSV are supported. Sinusoidal and simple load curves can also be generated quickly.

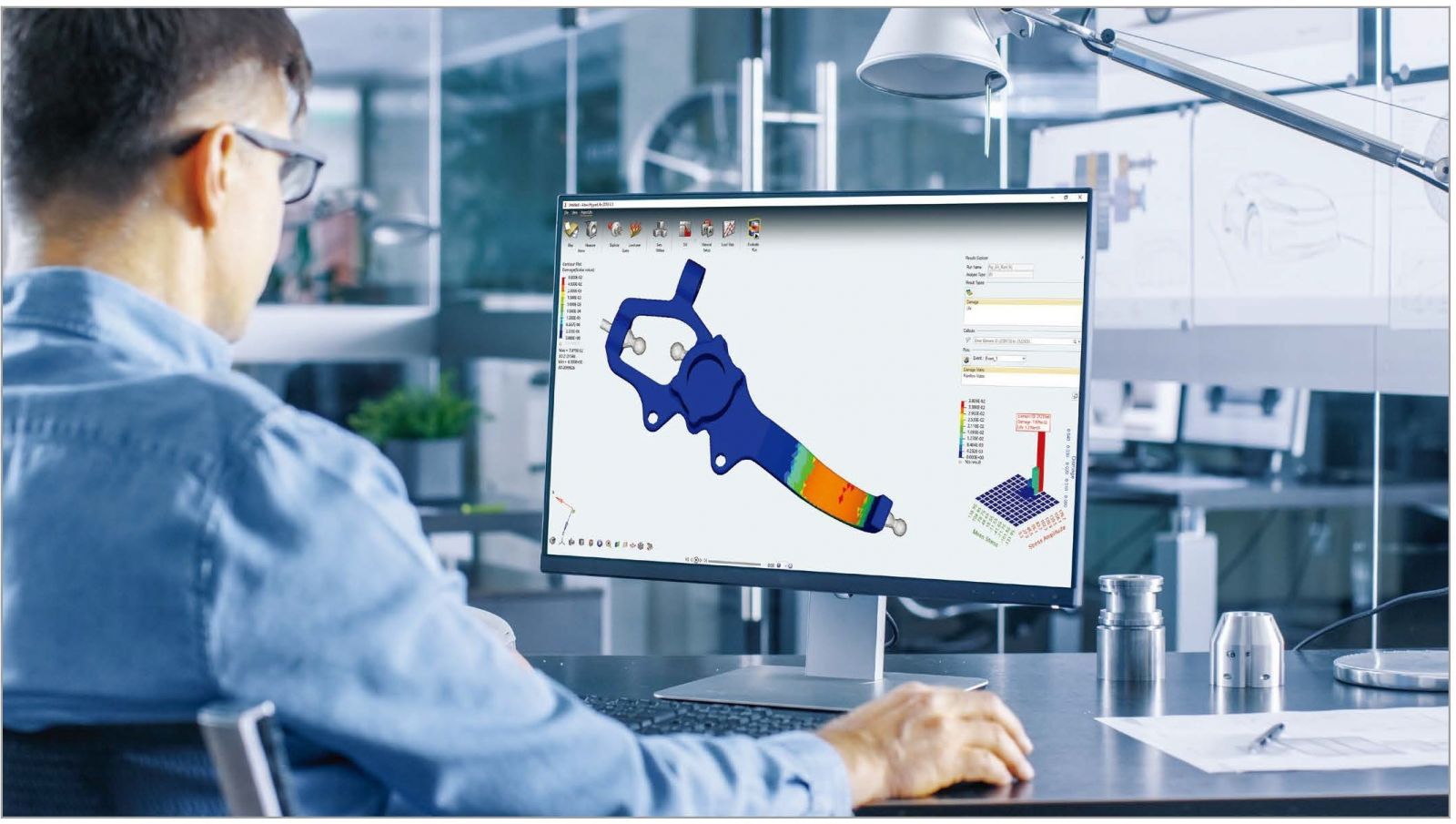

Fatigue parameters can be conveniently checked before submitting the calculation. After analysis, fatigue results can be read directly and displayed as contour plots of damage and life. Damage and cycle counts can also be displayed using bar charts. For the same FEA result file, analysis parameters can be quickly modified and recomputed.

|

Stree State

|

Mean Stress Correction

|

Plasticity

|

|

SN

|

Uniaxial

|

Abs Max

Principal

Max Principal

VONMISES

Signed von

Mises

TRESCA

signed TRESCA

signed Max

|

Shear

X Normal

Y Normal

Z Normal

X-Y Shear

Y-Z Shear

Z-X Shear

|

Goodman (Default)

Gerber

Gerber2

Soderberg

FKM

|

NA

|

|

Multiaxial

|

NA

(Stress tensors are directly used)

|

Goodman-Tension damage model

FKM-Tension damage model

Findley-Shear damage model

|

NA

|

|

EN

|

Uniaxial

|

Abs Max

Principal

Max Principal

Min Principal

VONMISES

Signed von

Mises

TRESCASG

SGTRESCA

|

SignedMax

Shear

X Normal

Y Normal

Z Normal

X-Y Shear

Y-Z Shear

Z-X Shear

|

Smith-Watson-Topper (SWT)

Morrow

Morrow2

|

Neuber

|

|

Multiaxial

|

NA (Stress tensors are directly used)

|

Smith-Watson-Topper(SWT)-Tension damage model

Fatemi-Socie Model (FS) - Shear damage model

Brown-Miller Model (BM)-Shear damage model

|

Jiang-Sehitoglu

Plasticity model-Non-proportional loding

(Default,not exposed.)

|

|

Welds

|

Method

|

Mean Stress Correction

|

Weld Elements

|

Plasticity

|

|

Seam

|

VOLVO

|

FKM

|

Shell elements

|

NA

|

|

Spot

|

RUPP

|

FKM

|

CBAR

CBEAM

CWELD

CHEXA

|

NA

|

Richin Technology is a “CAE and AI data analysis expert,” and we have completed numerous successful case projects.

▶ Contact us now at Contact Us to obtain more information.

▶ Subscribe to our Richin YouTube Channel to explore more CAE and data analysis content.