Altair ESAComp

Composite Analysis and Design

Altair ESAComp is composite analysis and design software that is suitable for early-stage design and later design verification of laminate structures.

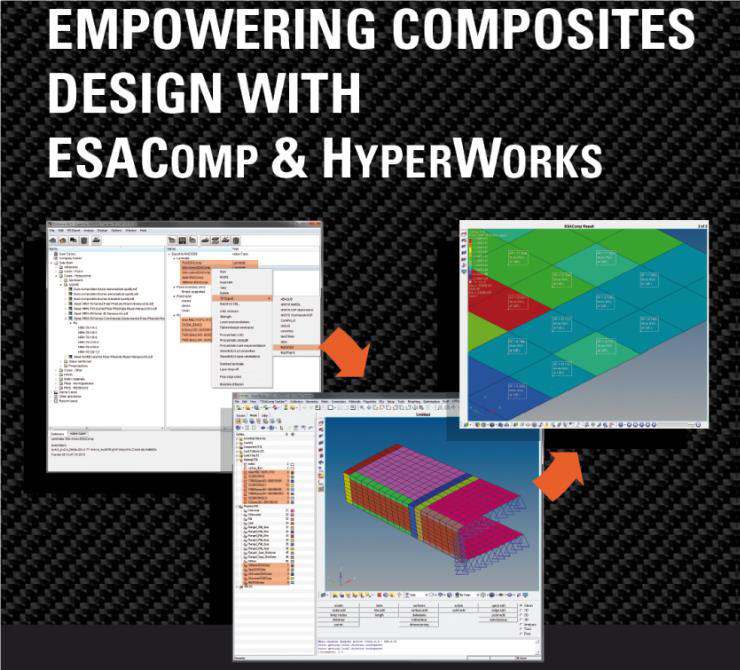

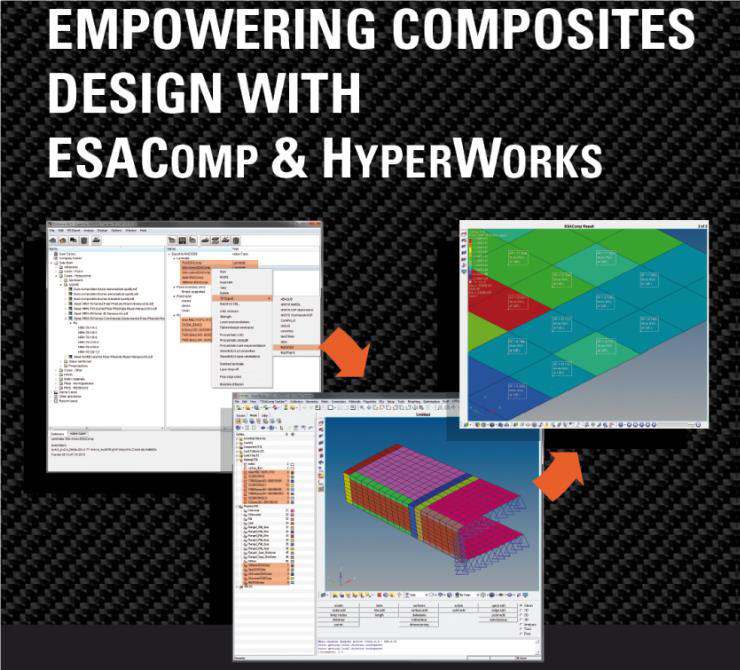

At the same time, some of its functions are also integrated into other composite-related software within Altair HyperWorks™.

【 Product Highlights 】

-

The material library provides more than 1,000 commercially available composite-related material properties

-

Covers both early-stage design and detailed design of composite structures

-

Standalone installation module with interfaces to traditional CAE software

-

Integration of ESAComp with HyperWorks improves pre- and post-processing efficiency for composites

-

Widely used in the composites industry worldwide

【 Advantages 】

-

Explore possible structural designs

-

There are many possible combinations of composite design and structural design. The ESAComp material library provides a basis for material selection for potential designs, and ESAComp’s analysis capabilities make rapid design and design trade-off studies possible.

-

High efficiency

-

Traditional finite element analysis is not suitable for early studies of laminate layups. ESAComp’s element-level composite layup analysis functions fully meet this need.

-

Avoid design defects

-

Composite design offers greater flexibility but is also more challenging. Without careful evaluation, potential design defects can easily be introduced.

ESAComp compensates for the shortcomings of traditional finite element analysis. Its advanced features, such as probabilistic analysis, are very useful when evaluating real designs.

-

Optimized design

-

ESAComp itself provides optimization capabilities for composite structures.

-

Easy to learn

-

To make it easier for users to learn, ESAComp provides a large number of examples stored directly in the software database,

which users can run directly. In addition, ESAComp also provides detailed theoretical documentation and model validation reports.

【 Features 】

ESAComp provides a large amount of composite material data. Users can also build their own material databases and related layup designs and store them in the software database. In addition to material data, the ESAComp database also includes information on plies, laminates, beams, plates, cylinders, adhesives, mechanical joints, loads, and boundary conditions.

ESAComp provides a highly efficient composite design platform. Result contour plots make it easy to evaluate and compare structural and material design choices.

ESAComp not only provides composite engineering documents that meet the needs of general engineers, but also theoretical documentation required by composite experts.

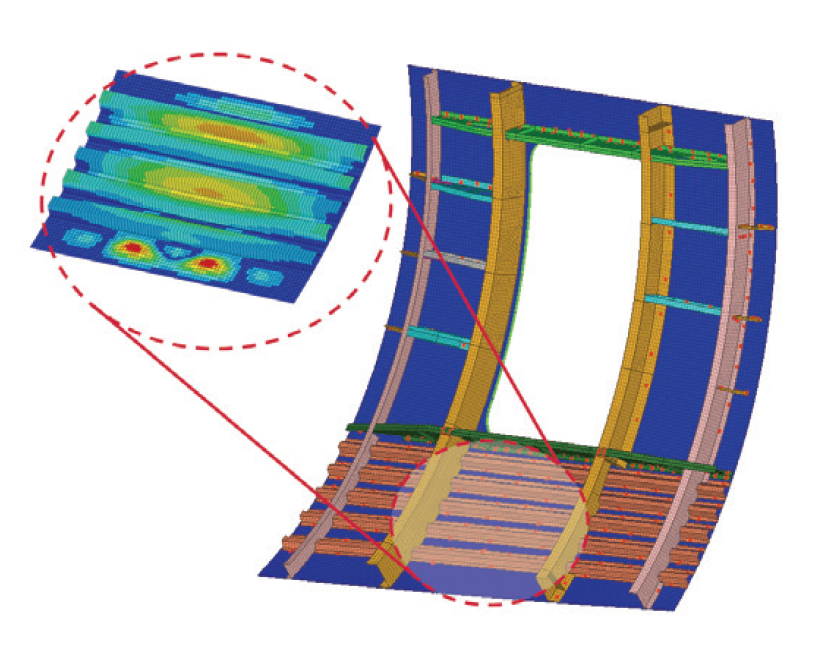

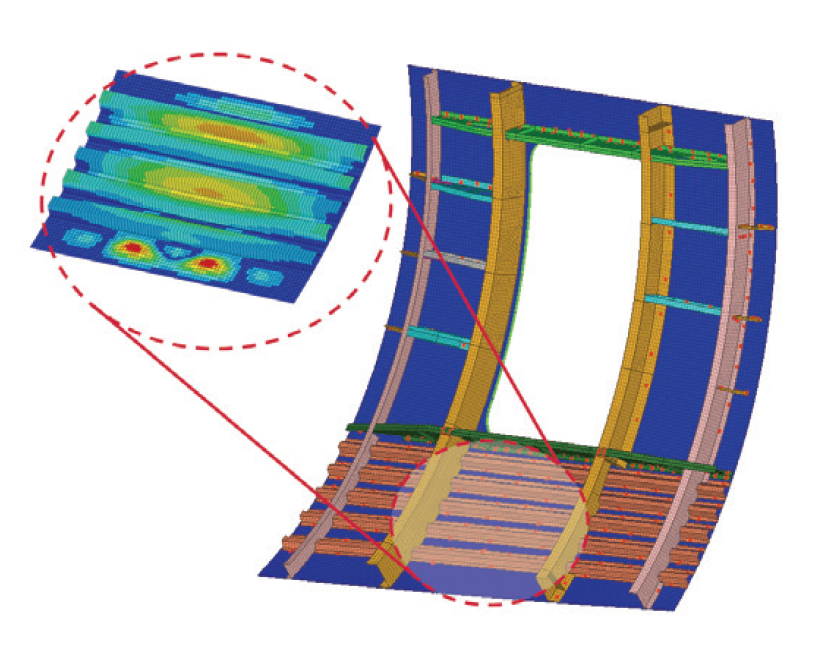

ESAComp provides a rich set of composite design tools enabling rapid modeling of flat plates, curved plates, beams, cylinders, cones, and pressure vessels. Based on micromechanics, it performs rule-of-mixtures analysis on composites (to calculate laminate stiffness), can carry out anisotropic thermal expansion analysis based on classical laminate theory (supports in-plane and out-of-plane failure analysis of laminates and stiffened panels, including advanced failure criteria such as puck2D / 3D and laRC03), buckling analysis, eigenvalue analysis, post-buckling analysis, as well as adhesive and mechanical joint analysis for composites, probabilistic analysis, moisture diffusion analysis, delamination analysis, and more.

Units and output formats can be switched at any time.

Supports user-defined extensions, batch runs, and integration into user workflows via Python scripts.

Layup designs and materials from ESAComp can be imported into HyperMesh (currently supported solver interfaces include OptiStruct, Nastran, Abaqus, Ansys, and LS-DYNA). Solver analysis results, material data, and layup information can also be transferred back to ESAComp for advanced failure analysis to obtain margins of safety, face sheet failure and core failure in sandwich structures—failure criteria that are generally not available in standard analysis software. These results can in turn be imported into HyperMesh Desktop to view contour plots, failure modes, and critical plies. In addition, ESAComp provides through-thickness result displays such as stress, strain, and margin of safety.

After importing laminate and load information from finite element models, users can fully leverage ESAComp’s tools to evaluate structural designs. Currently supported software interfaces for this workflow are OptiStruct and Nastran.

Richin Technology is a “CAE and AI data analysis expert,” and we have completed numerous successful case projects.

▶ Contact us now at Contact Us to obtain more information.

▶ Subscribe to our Richin YouTube Channel to explore more CAE and data analysis content.