Multibody System Modeling

.......Altair MotionView provides a user-friendly and easy-to-use multibody system modeling environment. Its built-in parametric and hierarchical modeling language enables users to quickly model, analyze, and improve mechanical systems before physical prototypes are available. Used together with the next-generation solver Altair MotionSolve, MotionView delivers a complete solution for multibody system simulation.

Further reading: [ Youtube ] Case Study – How to Use Software to Stabilize the Flight of a Mechanical Bird

【 Product Highlights 】

- User-friendly, solver-neutral multibody system modeling environment

- Hierarchical modeling

- Parametric modeling for rapid studies of design variables

- Extensible GUI and data model to support customer-specific development

- Automatic assembly of complex systems

【 Advantages 】

Accelerate Product Innovation

MotionView can create parametric models to help identify the best designs that meet the required targets.

Reduce Development Time and Cost

MotionView’s physics-based simulation capabilities allow users to evaluate design concepts early in the product development process. Once a model has been created and validated, it can be reused across different environments.

Improve Product Quality

MotionView enables users to perform what-if and stochastic analyses to study product performance, reducing the impact of manufacturing variation on product behavior.

Strengthen Corporate Quality Standards

MotionView can capture repeatable workflows to ensure consistent usage. Users can customize the interface to meet their own needs and leverage automation to reduce repetitive, scripted tasks, making it easier to standardize and share models, data, and result files with other users.

【 Features 】

Modeling Environment

MotionView provides multiple capabilities that simplify the modeling of complex mechanical systems.

-

Supports importing CAD geometry from all major formats

-

Supports importing intermediate geometry formats such as Parasolid, STEP, IGES, etc.

-

Hierarchical modeling language makes it easy to build complex models

-

Parametric modeling streamlines subsequent DOE analysis and optimization

-

Supports symmetry modeling to reduce data input

-

Conditional logic allows a single system to represent multiple topologies

-

Process-driven wizards quickly automate model assembly

-

Easy import of test data

-

Supports Altair MotionSolve and Adams

-

Five-step workflow wizard to quickly define system optimization models

Intuitive User Interface

MotionView’s intuitive user interface enables both experienced and novice engineers to quickly build and analyze multibody systems.

-

Built-in processes streamline and standardize mechanical system modeling

-

Modern UI and graphics window with integrated context menus make the software easier to use

-

Project browser with context menus plus search and filter functions enables fast model navigation

-

Rich toolbars support fast model creation, editing, and control

Automation and Customization

MotionView is fully customizable, allowing users to tailor the environment to their specific needs.

-

Define custom entities using the MDL language

-

Customize panels and menus to support entity creation

-

Submit models for solution and retrieve results

-

Use scripting languages to automate repetitive modeling tasks and reduce mouse operations

-

Export component loads in finite element or fatigue formats for strength, fatigue, and optimization calculations

-

Generate customized reports

Toolkits

MotionView offers a series of specialized toolkits for rapid modeling of complex systems.

-

Leaf spring toolkit: parametric modeling, assembly, preload calculation, stiffness testing, and correlation for various leaf spring systems

-

Tracked vehicle toolkit: modeling and assembly of chains, sprockets, idlers, support rollers, tensioners, and various wheel systems, with integration to control systems and operating environments

-

Driveline toolkit: rapid modeling of belt and chain drive systems

-

MIT toolkit: modeling hydraulic and rubber bushings and fitting stiffness characteristics

-

Load export toolkit: directly output loads in OptiStruct, NASTRAN, NCODE, MTS, and other formats

Complete Solution

MotionView supports modeling–analysis–post-processing–optimization for multibody systems within a single environment, eliminating the need to switch between different products.

-

Modeling: graphically build and assemble complex multibody systems, submit jobs, and directly solve with MotionSolve and Adams.

-

Post-processing: correlate simulation results with test data, calculate performance metrics, plot curves, review animations, and generate reports to summarize system behavior.

-

Optimization: use HyperStudy for DOE, optimization, and stochastic studies to understand system performance, and OptiStruct for component-level optimization.

【 Automotive Solutions 】

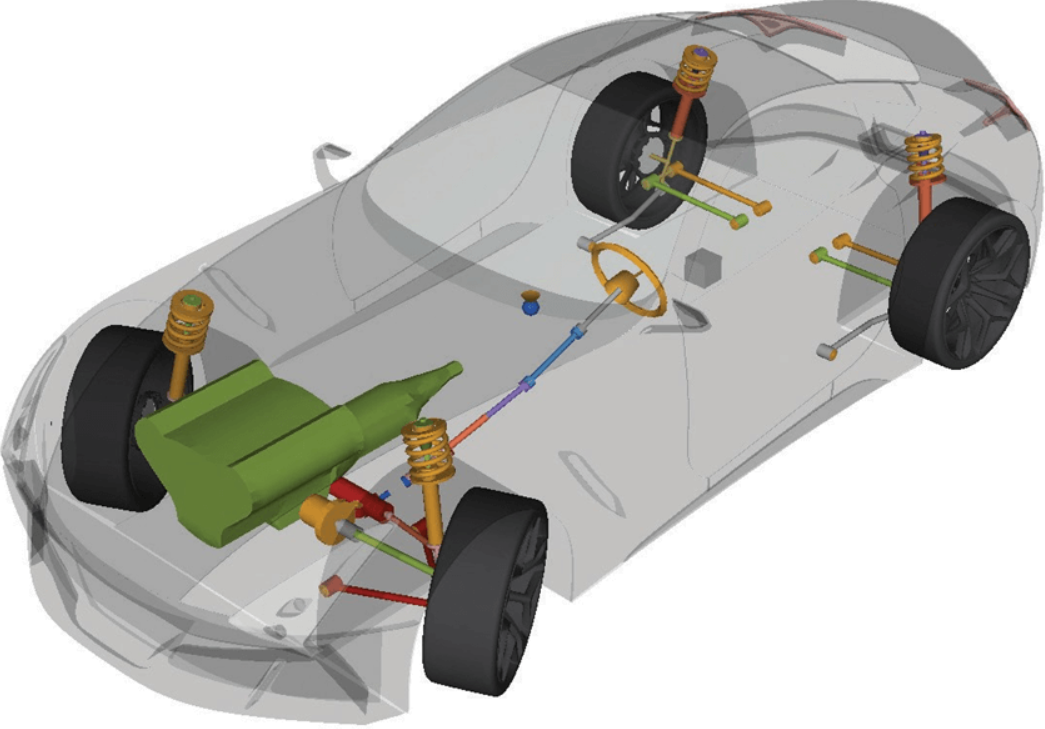

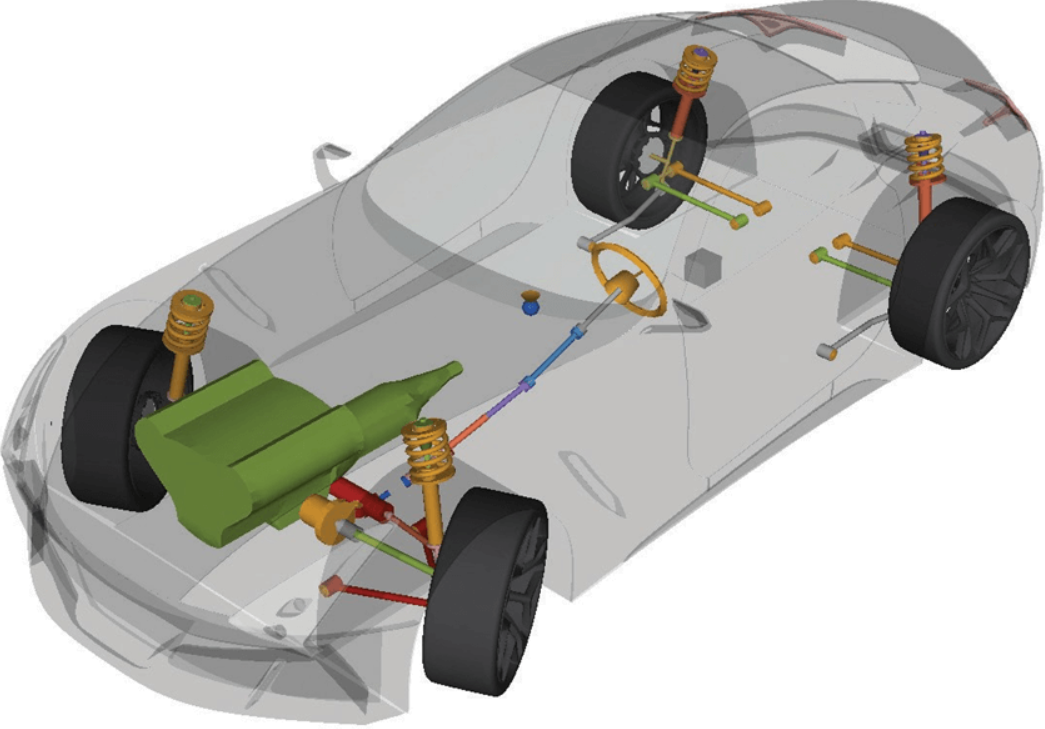

.......MotionView provides a rich set of tools for passenger car and truck modeling, including an advanced, professional model library for full-vehicle models with tires, road surfaces, drivers, springs, bushings, bump stops, dampers, and more. Users can also add their own components to the library. MotionView supports assembly wizards for models and test events: with just a few mouse clicks, you can select front and rear suspension architectures, powertrain, tires, and road profiles to rapidly assemble a full vehicle model. Standard suspension and handling test scenarios can be simulated, component loads required for strength and fatigue analysis can be calculated, and reports can be generated automatically.

【 General Machinery Solutions 】

.......MotionView can import CAD or finite element models to quickly create multibody systems. It supports all major import formats and automatically calculates component mass properties. Users can easily create 2D and 3D contact between complex geometries and import data from CSV files to define hard points. Generalized joints—including stiffness, friction, and limits—can be defined, and belt, gear, rope, and pulley systems can be created rapidly. These core capabilities ensure fast model assembly and robust solution of analysis events.

Richin Technology is a “CAE and AI data analytics expert”, and we have completed many successful case studies.

▶ Contact us now to get more information.

▶ Subscribe to our Richin YouTube channel to explore more CAE and data analytics content.