.......MotionSolve is a specialized tool for multibody system analysis and optimization, providing powerful modeling, analysis, visualization, and optimization capabilities for simulating complex mechanical systems. MotionSolve analysis capabilities include kinematics, dynamics, statics, quasi-statics, linear, and vibration analysis, helping users better understand and improve product performance.

|

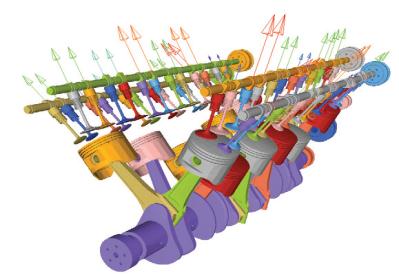

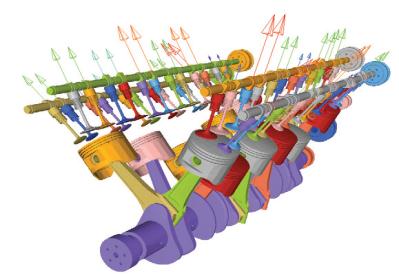

2D contact simulation

|

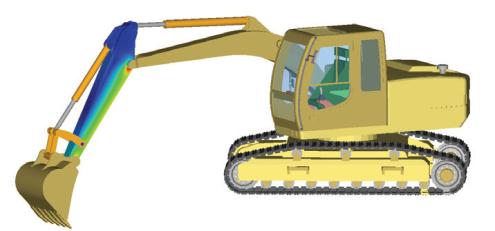

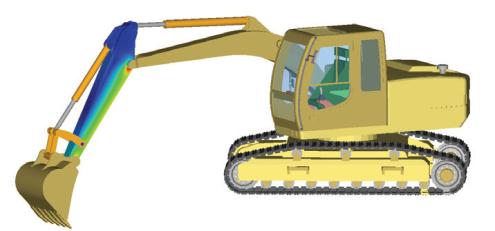

Excavator flexible-body simulation

|

UAV dynamics analysis

|

【 Product Highlights 】

-

A comprehensive multibody dynamics solution to optimize mechanical system performance

-

Convenient and efficient mechanisms modeling, analysis, verification, and optimization

-

Proven across multiple industries such as automotive, aerospace, and general machinery

-

Extensive correlation between experimental data and simulation results through customer collaborations

【 Advantages 】

Shorten product development cycles: build simple models in the early design phase, and gradually increase model complexity as development progresses. MotionSolve provides a wide range of modeling elements and analysis methods to support this process. By leveraging virtual simulation to reduce the number of physical tests, better designs can be achieved more quickly.

Improve product quality

MotionSolve can build multibody models that realistically represent user-specific concerns, accurately solving models that reflect product performance and checking whether the product meets the required performance targets.

Accelerate product innovation

Use Design of Experiments (DOE) and stochastic analysis to simulate and optimize product performance. Combined with OptiStruct, MotionSolve-computed loads can be used for weight reduction and performance optimization.

Reduce design and production risk

Virtual simulation enables fast evaluation of a large number of concept designs, making it possible to select the optimal solution. As the design evolves, existing models can be used to validate updated designs.

【 Features 】

Modeling

.......MotionSolve provides a complete set of modeling elements, enabling users to create any complex multibody system. MotionSolve also integrates CAD, FE, control systems, mechatronics simulation, CFD, and optimization.

Modeling capabilities include:

Analysis

MotionSolve can evaluate the dynamic characteristics of systems, study vibration behavior, assess control system performance, and compute loads for predicting component fatigue life and improving system performance. These tasks can be accomplished using the built-in analysis methods, and users can also create their own analysis procedures.

MotionSolve provides multiple capabilities to study system behavior

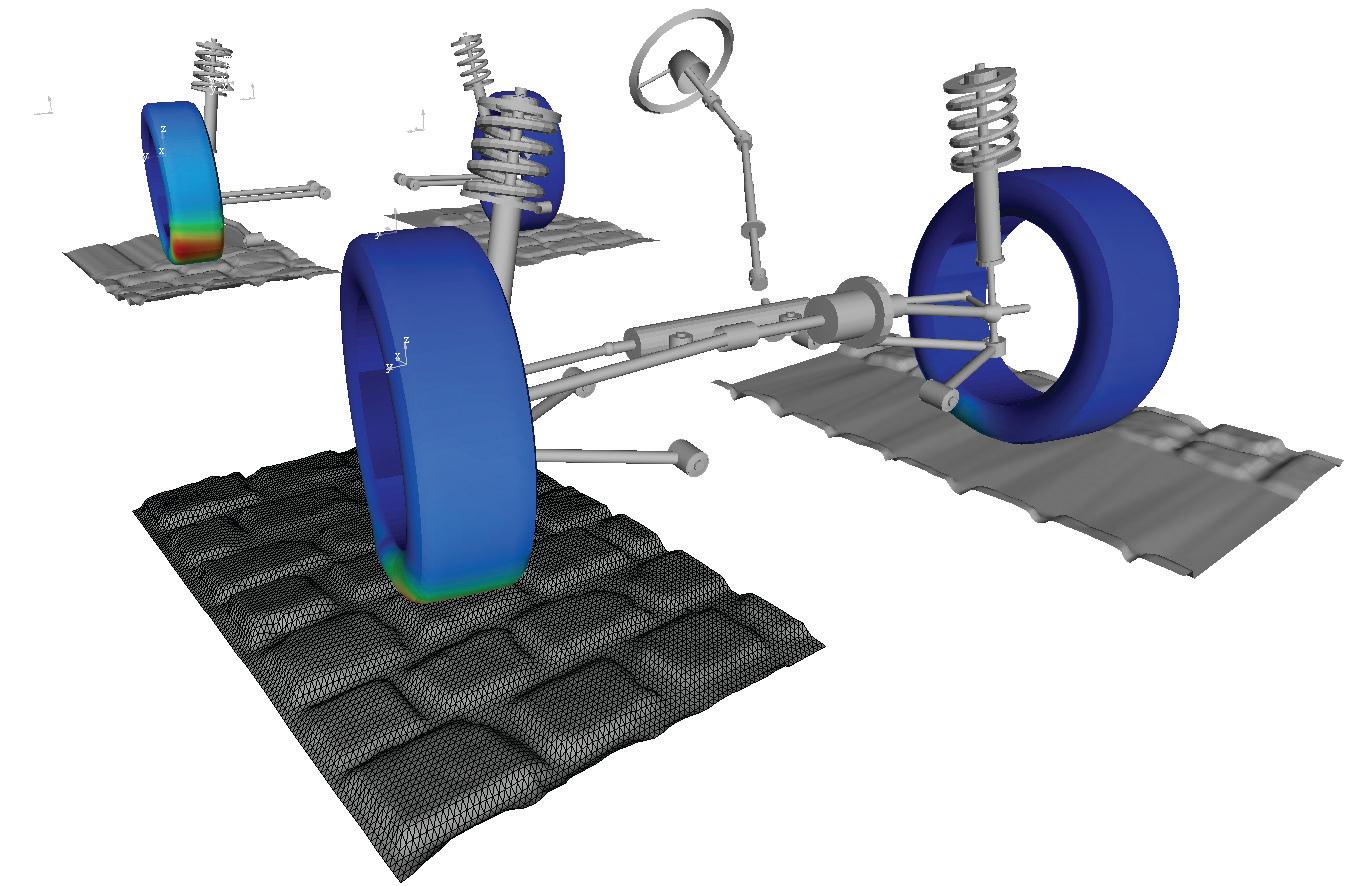

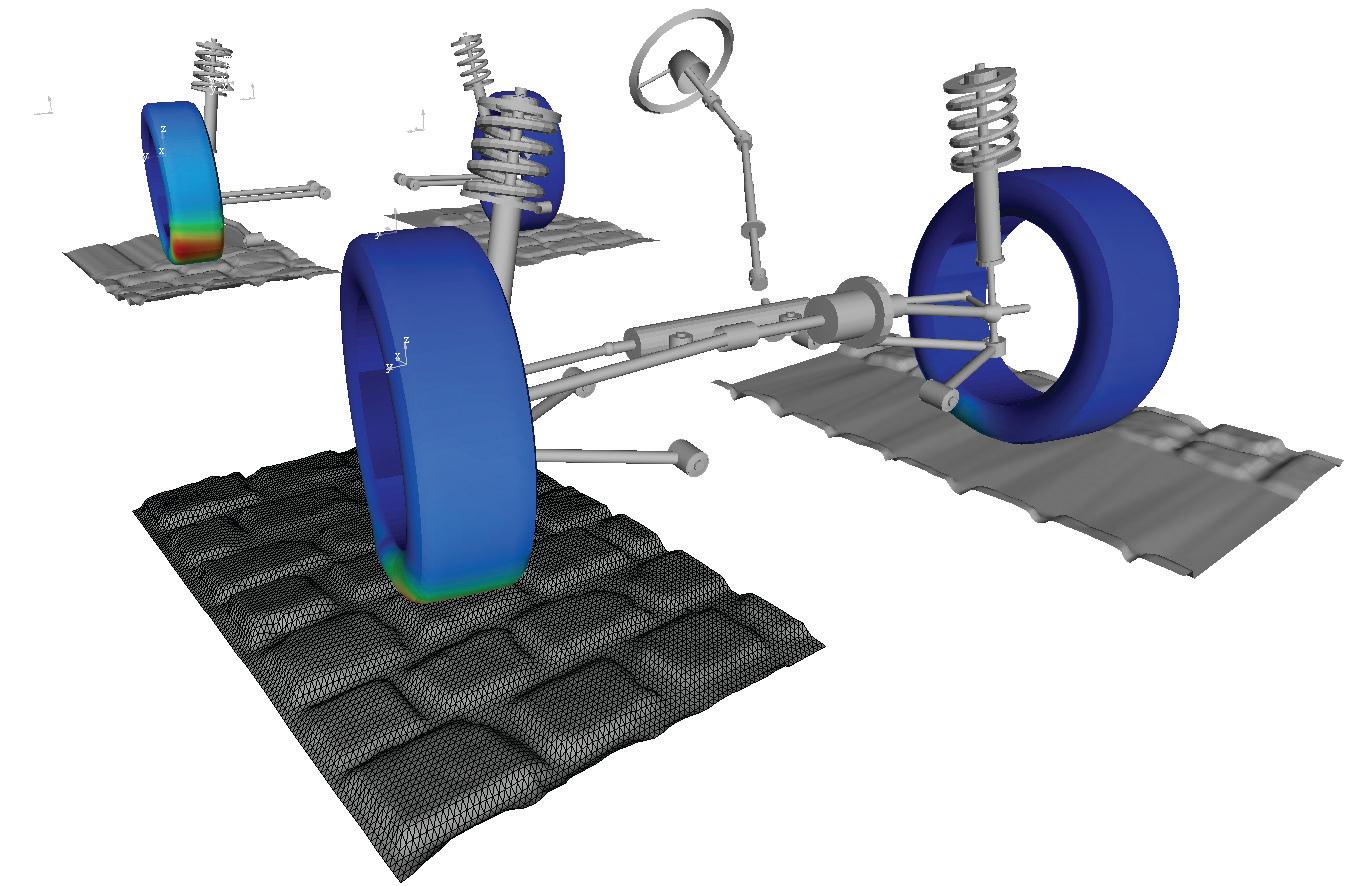

Vehicle dynamics, fatigue, and NVH solutions

MotionSolve provides a complete solution for automotive simulation, including parameterized libraries of vehicle component models that help users quickly build subsystems. MotionSolve supports tire models such as FTire, TNO Delft-Tyre, CDTire, and the OpenCRG standard, offering different tire and road models for real-world applications. Templates cover common suspensions, steering systems, and leaf-spring systems, and a guided assembly process allows for rapid model assembly to analyze half-vehicle conditions, full-vehicle handling scenarios, and user-defined events. Automated report generation helps quickly evaluate vehicle dynamics behavior. These capabilities are well suited for studying vehicle dynamics performance, computing loads for component fatigue durability analysis, and assessing vehicle NVH performance.

General mechanical system solutions

MotionSolve provides comprehensive contact capabilities, enabling fast creation and analysis of complex systems with thousands of contacts. Similar to automotive workflows, users can create parameterized components, templates, and subsystems, and assemble models using guided processes. Automated report generation helps quickly evaluate and understand system characteristics and share results with others.

Control systems and mechatronics solutions

MotionSolve can be integrated with 1D and control-system software for co-simulation.

-

In the early design stage, linearized multibody models from MotionSolve can be exported as state matrices to control-system tools for control design.

-

In the evaluation stage, high-fidelity MotionSolve multibody models can be exported to solidThinking / Activate, Matlab, or Simulink to evaluate control systems. In the 1D or control-system environment, these can be connected to multibody systems for data exchange, running the coupled system to assess overall performance.

-

Supports FMI / FMU 2.0 standards, allowing further expansion of models.

HyperWorks integration

HyperWorks provides a complete multibody system simulation environment. You can:

-

Quickly build multibody models in MotionView® and HyperMesh®

-

Solve them in MotionSolve®

-

Post-process in HyperView® and HyperGraph®

-

Use customized scripts in solidThinking Compose for advanced post-processing

-

Generate flexible bodies in OptiStruct® to improve model accuracy

-

Perform DOE studies, system-level optimization, and stochastic analysis in HyperStudy®

-

Use MotionSolve-computed loads in OptiStruct for component-level optimization

-

Couple with AcuSolve® to solve problems involving both rigid-body motion and fluid loads

Richin Technology is an expert in CAE and AI data analytics, and we have completed many successful case studies.

▶ Contact us now to get more information.

▶ Subscribe to the Richin YouTube channel to explore more CAE and data analytics.