AcuSolve is Altair’s most powerful computational fluid dynamics (CFD) tool. AcuSolve provides users with a rich and comprehensive set of physical models. Thanks to its robust and scalable solver technology, AcuSolve can easily simulate flow, heat transfer, turbulence, non-Newtonian fluids, and more. These thoroughly validated physical models deliver unmatched accuracy on unstructured meshes. This means users spend less time building mesh models and gain more time to focus on product design.

Extended reading: 【Youtube】Fluid–structure–acoustic coupling analysis of an automotive panel

|

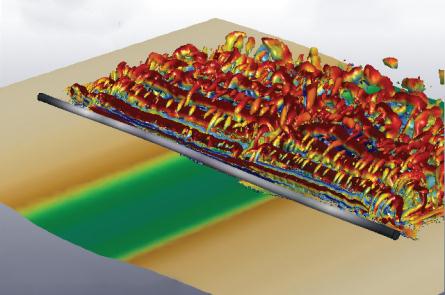

海底輸油管路渦致

振動的固體變形和流場

|

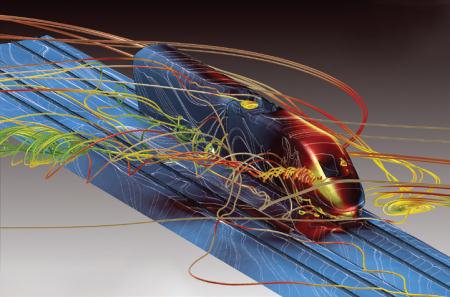

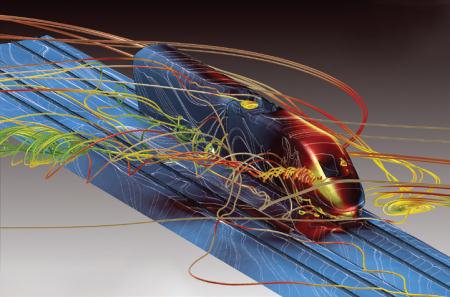

火車在橫風中的壓力場和流線

|

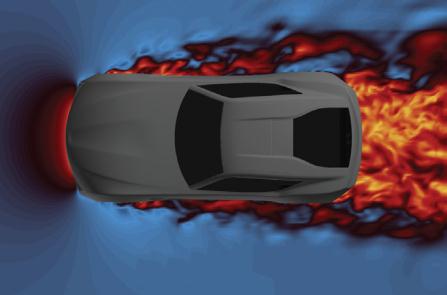

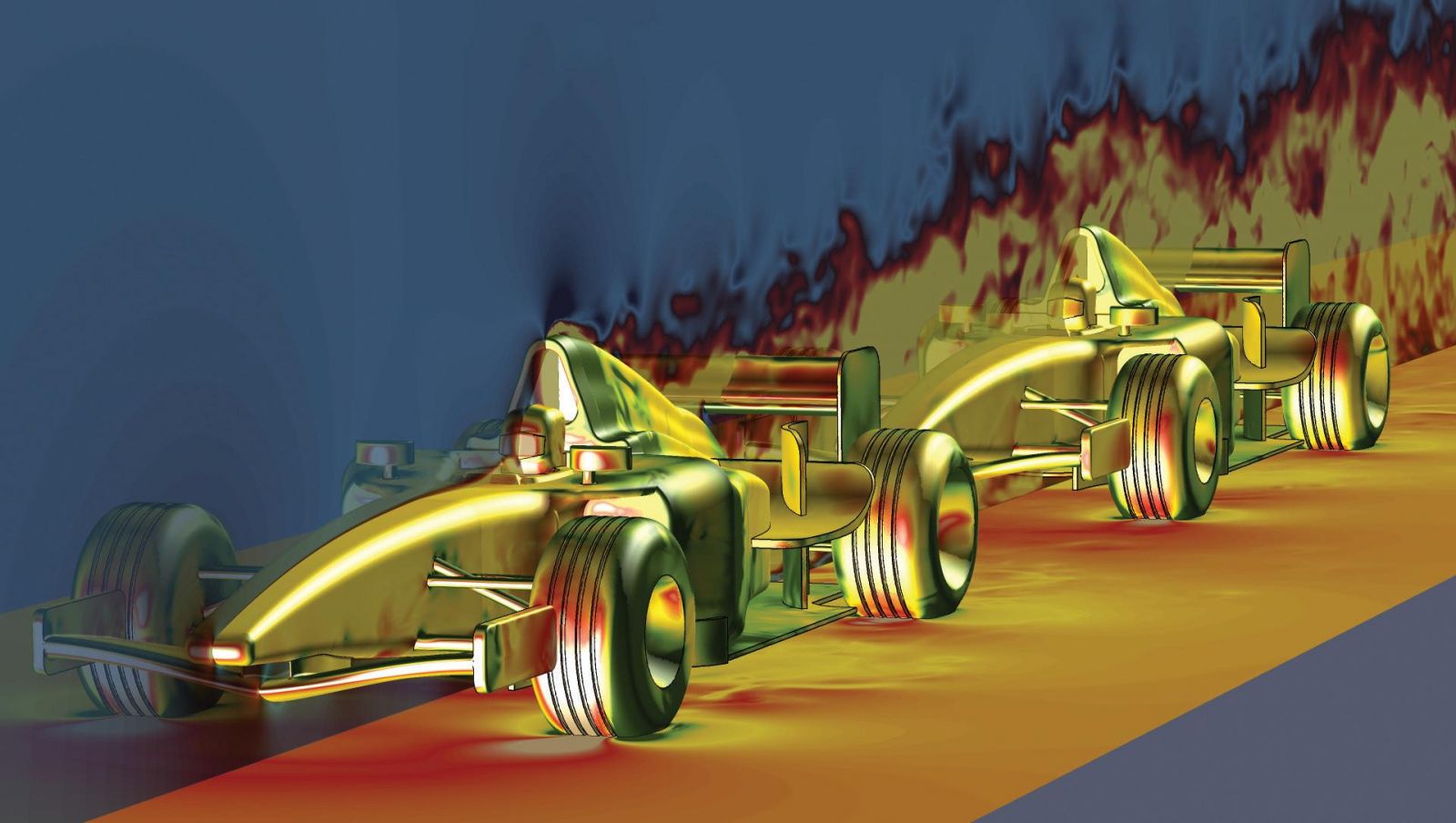

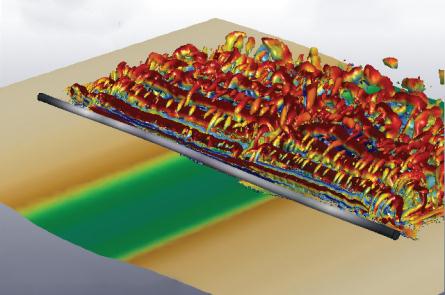

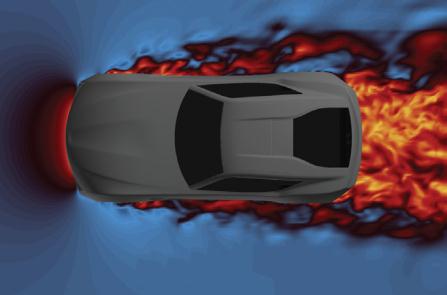

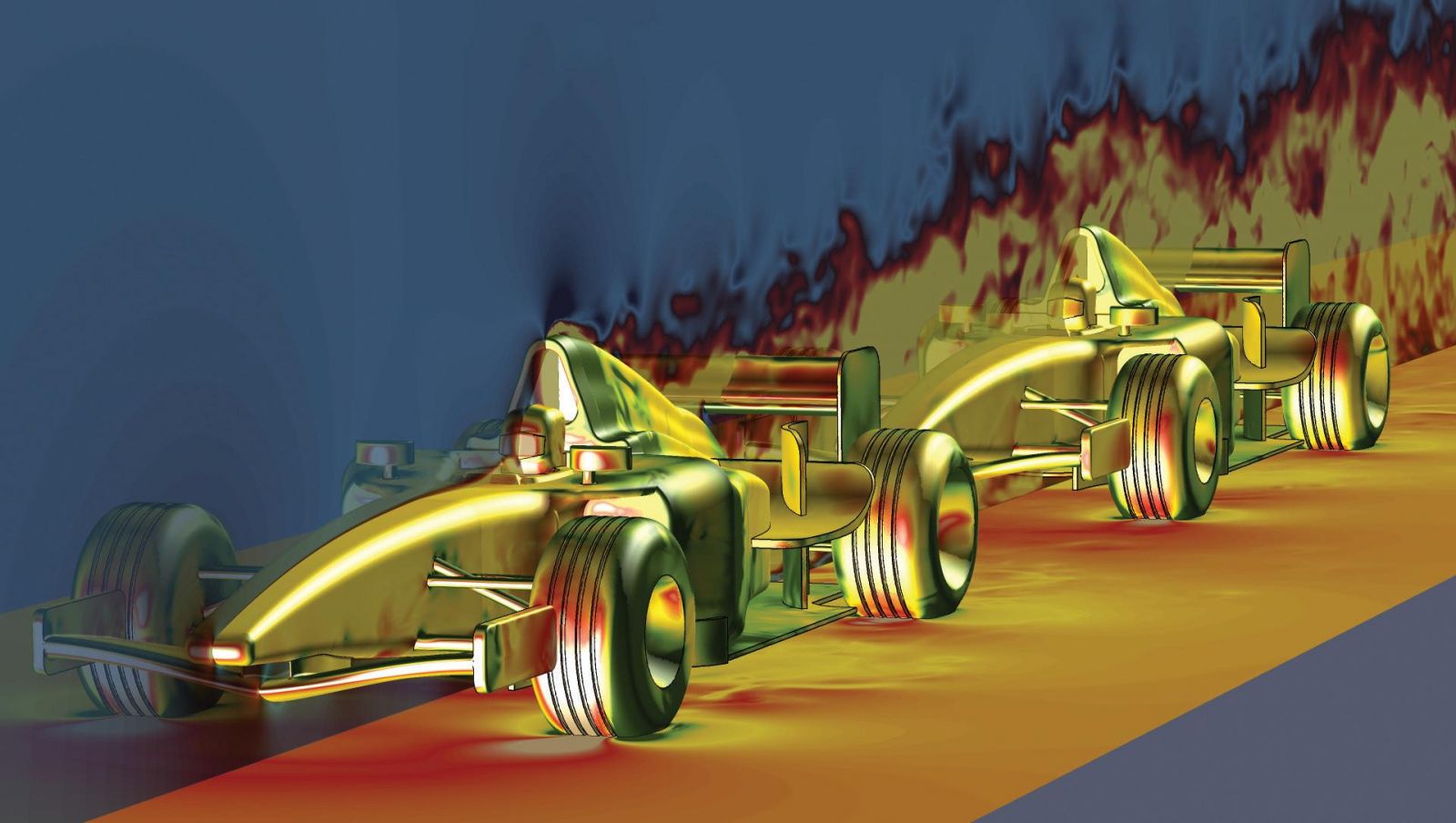

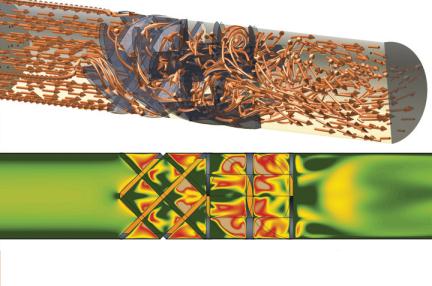

賽車的大渦模擬流場

|

|

【 Product Highlights 】

-

Highly efficient and flexible workflow

-

Comprehensive physical models, including flow, turbulence, heat transfer, and immiscible multiphase flows

-

Maintains accuracy and stability even on highly distorted meshes

-

Fast, efficient algorithms for both steady-state and transient simulations

-

Excellent parallel performance scaling

-

Advanced multiphysics capabilities, enabling fluid–rigid body and fluid–flexible body coupling through Altair solvers and third-party codes

【 Advantages 】

The philosophy of AcuSolve is that users should not have to sacrifice robustness and ease of use in order to obtain highly accurate simulation results. Users no longer need to spend days or even weeks tuning mesh quality; they simply generate the mesh, submit the run, and review the results — it’s that straightforward.

Advanced physical models

Are the problems you encounter challenging the capabilities of your solver — turbulent vortices, immiscible multiphase flow, fluid–structure interaction, and other complex phenomena? AcuSolve can easily handle these types of problems. You don’t need to struggle with solver options such as differencing schemes, time integration, CFL constraints, and so on. All supported flow features are handled by a single solver, without having to retune these parameters for different analysis cases.

High speed and parallel computing capabilities

To get the most value from CFD simulations, it is often necessary to evaluate various design alternatives early in the product development cycle, which places strict demands on the solver for fast turnaround.

AcuSolve’s strengths in this area are mainly reflected in:

-

A fully coupled pressure–velocity algorithm that enables fast convergence of nonlinear equations.

-

An efficient parallel architecture providing distributed, shared, and hybrid parallel modes.

-

Excellent speed-up performance, even on systems with thousands of CPU cores.

【 Simulation Capabilities 】

Flow simulation

AcuSolve focuses on the simulation of incompressible and subsonic compressible flows. For these problems, both Newtonian and non-Newtonian fluid material models are comprehensively supported. For special flow regimes such as Stokes flow, in addition to the Navier–Stokes equations, a dedicated Stokes formulation is available.

Heat transfer and radiation models

AcuSolve provides comprehensive heat transfer models for both fluids and solids, including:

-

Conjugate heat transfer

-

Natural convection

-

Enclosed cavity radiation

-

Solar radiation

-

Thermal shell elements for thin plates

-

Simplified heat exchanger models

Turbulence models

AcuSolve provides a complete set of RANS turbulence models commonly used in industry:

For high-accuracy transient analysis, the following models are supported:

-

Detached eddy simulation (DES and DDES) based on the Spalart–Allmaras formulation

-

Detached eddy simulation based on the SST two-equation model

-

Large eddy simulation (LES) with fixed or dynamic coefficients

For simulations involving transition to turbulence, AcuSolve provides the following transition models:

-

γ single-equation model

-

γ–Reθ two-equation model

BETA feature: Multiphase flow

The AcuSolve multiphase flow model can simulate two immiscible incompressible fluids. Multiphase flow can be combined with heat transfer, turbulence, moving and deforming meshes, sliding meshes, and fluid–structure interaction. There is no restriction on the density ratio of the two fluids, allowing simulations such as water–air or water–oil.

Moving mesh

AcuSolve provides two approaches for handling moving meshes. For complex motions, the arbitrary Lagrangian–Eulerian (ALE) method can be used. For simpler motion, boundary condition tools can be used to directly prescribe motion on boundaries and internal mesh regions.

User-defined functions (UDF)

AcuSolve allows users to create user-defined functions to specify material properties, boundary conditions, source terms, and other features. A client–server programming mode is also supported, enabling coupling between CFD models and external codes such as control system software.

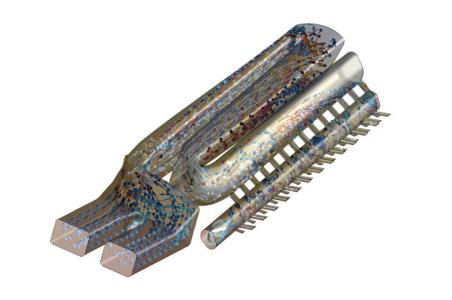

Multiphysics

AcuSolve’s advanced multiphysics capabilities benefit from its transient simulation and mesh deformation features.

Without coupling to external codes, AcuSolve can directly realize:

Through linear structural deformation and coupling with other HyperWorks modules, the following can be achieved:

-

Finite-mass particle tracking (coupled with AcuTrace)

-

Multibody dynamics (coupled with MotionSolve)

-

Nonlinear structural deformation (coupled with RADIOSS)

Pre-processing capabilities

The graphical user interface of AcuSolved, AcuConsole, includes a rich set of setup options that help users quickly build CFD models. The AcuConsole interface exposes all AcuSolve capabilities and supports both interactive graphical workflows and automated batch-processing scripts.

Post-processing capabilities

AcuSolved uses the AcuFieldView module for post-processing, an OEM version from Intelligent Light. It provides a client–server parallel interactive mode that enables batch post-processing of simulation data.

|

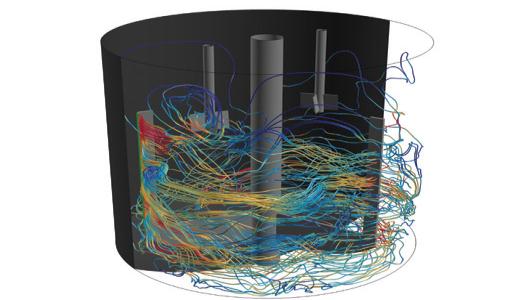

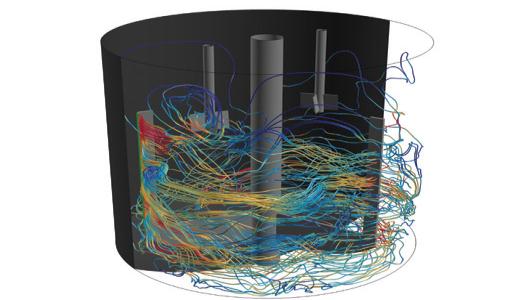

攪拌器中顯示流態的流線圖

|

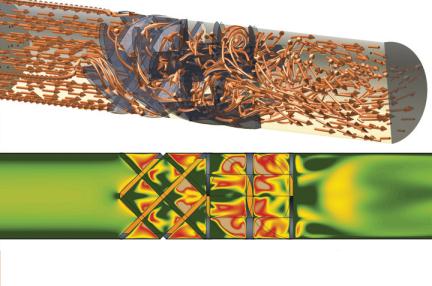

優SMX 靜態混合器的流場

|

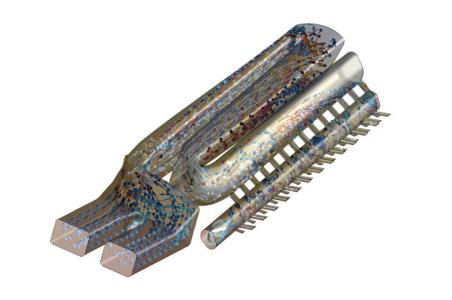

汽輪機葉片熱固耦合模型的流線

|

Richin Tech is the "expert in CAE and AI data analytics", and we have completed many successful case studies.

▶ Contact us now to get more information.

▶ Subscribe to the Richin YouTube channel to explore more about CAE and data analytics.