Background

For large electromechanical components such as high- and low-voltage transformers and distribution panels, the heat generated can be quite significant. Ventilation capacity is often evaluated using empirical formulas, but such methods can be too rough and cannot accurately predict the real temperature distribution. For example, factors like fan placement, airflow direction, and the blocking effect of internal structures in the enclosure cannot be properly accounted for using simple empirical calculations.

As equipment power density increases—for instance, for a common 500KVA transformer—improper heat dissipation may cause the temperature rise to exceed the allowable range, which can in turn affect equipment lifespan and operational safety.

Considering the above, the customer in this case commissioned Richin to perform thermal analysis using CFD software, simulating internal airflow, heat conduction, and convection phenomena, and evaluating the temperature distribution of each component under full-load operation.

By explicitly defining the heat sources (such as copper loss and iron loss), intake and exhaust openings, and fan ventilation conditions, the airflow paths and heat dissipation efficiency inside the panel can be computed. This also enables further optimization of fan layout, inlet and outlet opening sizes, or even internal panel arrangement, thereby improving overall thermal performance.

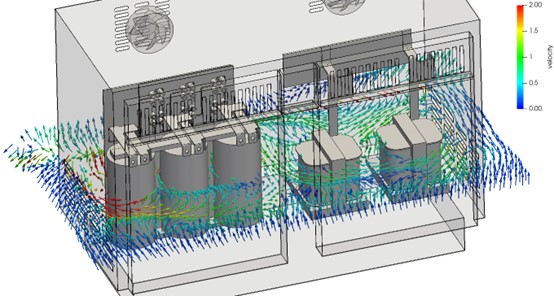

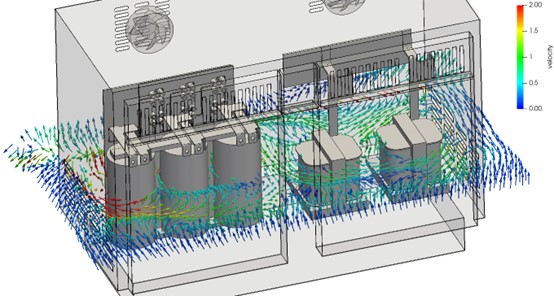

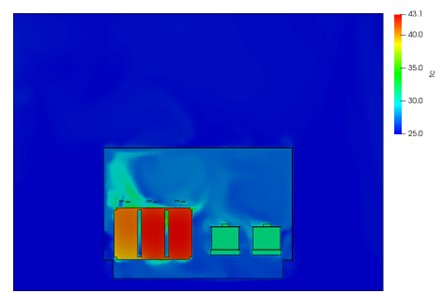

Transformer airflow cross-section view

Results

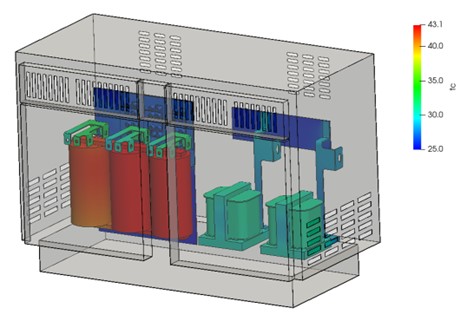

In this project, Altair SimLab was used as the pre-processor for model building, while AcuSolve served as the flow solver to perform thermal analysis of the transformer panel. The analysis included fan cooling, surrounding airflow, and natural convection effects, providing a highly realistic thermal simulation based on the actual transformer configuration.

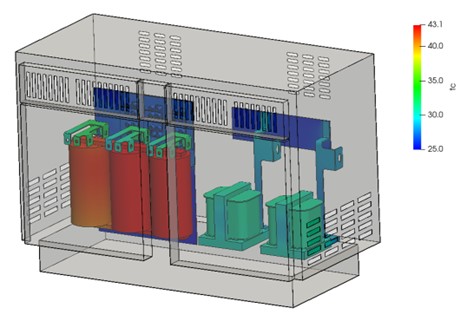

The analysis results showed that the maximum temperature in some regions exceeded the allowable upper limit. After adding extra ventilation openings and making design improvements, the thermal performance met the customer’s requirements.

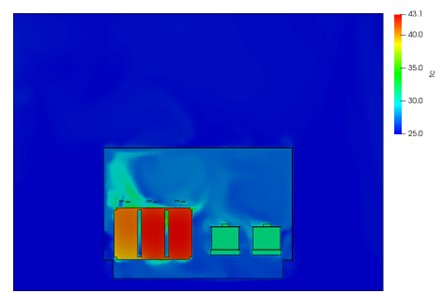

Transformer temperature cross-section view

Temperature distribution of each component

Technical Highlights

-

Altair SimLab as the pre-processor combined with the AcuSolve solver can preserve as much geometric detail as possible, including ventilation grilles, individual busbars, and more, thereby fully capturing their influence on airflow behavior.

-

CFD analysis clearly reveals the maximum temperature of each component and its temperature distribution. Post-processing results also show that the 500KVA transformer located near the outer side experiences lower temperatures than the other two units because it is closer to the inlet opening.

Extended Applications

Beyond evaluating the maximum temperature under rated operating conditions, CFD can also be applied in the following scenarios:

1. Abnormal condition simulation and thermal risk assessment

In addition to thermal analysis under normal operating conditions, CFD can be used to simulate abnormal situations such as fan failure, clogged filters, or blocked inlets/outlets, in order to estimate temperature changes and potential overheating risks under worst-case scenarios.

2. Smart monitoring and model validation with temperature data

By integrating real temperature sensors with IoT technologies, CFD results can be compared and calibrated against field measurements to build a more realistic Digital Twin system. This can then be used for real-time thermal monitoring and predictive maintenance.

3. Design automation and optimization

CFD can be embedded into the design workflow and combined with parametric modeling and optimization algorithms to automatically identify the best configuration for inlet/outlet openings, fan specifications, and baffle designs, achieving optimal thermal performance and cost efficiency. This is especially valuable for diverse, customized panel designs.

4. Space planning and equipment layout analysis

In applications with limited space, such as large substations or data centers, CFD can be used to evaluate the thermal interaction when multiple distribution panels or transformers are operating in parallel. This helps determine optimal spacing between equipment and the configuration of HVAC and ventilation systems to avoid local hot spots.

5. Evaluating the impact of environmental conditions on performance

CFD can also simulate different installation environments—such as high temperature and humidity, low airflow, or dusty conditions—and their influence on cooling performance. This supports the selection of appropriate protection ratings and cooling strategies, especially for outdoor transformer enclosures or special industrial environments.

Richin Tech is the "expert in CAE and AI data analytics", and we have completed many successful case studies.

▶ Contact us now to get more information.

▶ Subscribe to the Richin YouTube channel to explore more about CAE and data analytics.